NOMINAL SIZE

- 1", 1-1/2", 2", 3", 4", 6", 8", 10", and 12"

- 14" through 40" sizes are available upon request.

- Available EN 12874:2001 Certified Model.

CONNECTIONS

- ANSI/ASME B16.5 Class 150 Flange

- KS/JIS 10K Flange

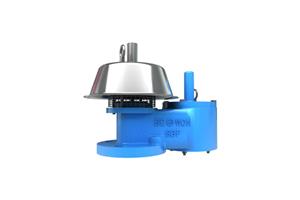

Protect process line or system from potential ignition source Easy installation and simple mechanism Available in size 1” to 40”

Drilling conforming to ANSI/ASME B16.5 for class 150 flanges, or KS/JIS 10K flanges In-line type model installed process line system which flammable gas or vapor flows.

Bi-directional Flame Arrester and should be installed within 20 times the pipe diameter from a potential ignition source.

▶ Consult our factory for special application.

Specifications

| Installation | Vertical, recommend Required drain plug for horizontal installation |

|---|---|

| Type | In-line flame arrester |

| Classification | Deflagration flame arrester, Bi-directional |

| Normal working pressure | Below 1.0 barg(standard speciafication) |

| Explosion gas group | IIA(standard), IIB/IIC(for special application) |

Materials

| PART NAME | MATERIALS STANDARD | MATERIALS OPTIONAL |

|---|---|---|

| Body | Carbon Steel, 304 S.S, 316 S.S,Aluminum | Hastelloy, Alloy 20, Monel, Inconel |

| Flame Element | 304 S.S, 316 S.S | Hastelloy, Alloy 20, Monel, Inconel |

| Element Housing | 304 S.S, 316 S.S | Hastelloy, Alloy 20, Monel, Inconel |

| Stud Bolt and Nut | C.S, 304 S.S | 316 S.S |

Basic Ordering Information

1. Model and type

2. Fluid Handling

3. Operating Temperature & Pressure ranges

4. Size and Connection

5. Material

6. Distance from potential ignition source