Motivation for Development

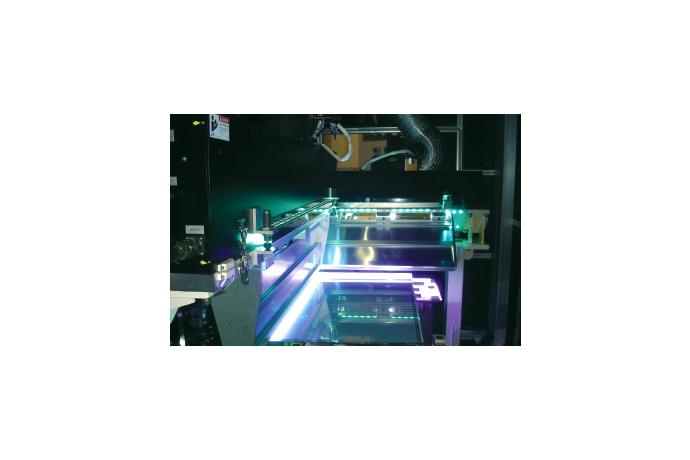

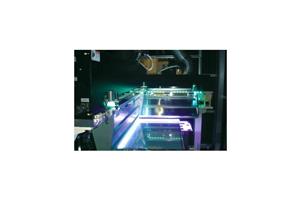

The curing machine which is necessary for the process of attaching and sealing the upper and lower panels in the LCD process has two processes of the strip process and the reverse process, in a manner that covers hides the parts not needed to be cured and cures the front. Designed to make it possible to UV-irradiate only the necessary parts by adopting the light guide method to fit the needs of customers, and developed to process products sensitive to UV rays. Also, this is an excellent curing machine which focuses on increasing productivity twice, reducing the process, and making zero the angle of light irradiation and the risk of damage to the liquid crystal.

Main Use : For LCD TFT and C/F bonding- and sealing-manufacturing process

Product Features

① Increase the productivity twice and reduce the process by applying the light guide

② Reduce the defective rate absolutely and remove the risk of damage to the liquid crystal due to UV rays, by allowing the angle of light irradiation to be controlled

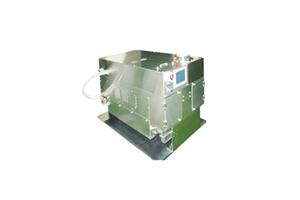

③ This is the optimized model developed and applied for the main sealing of panels of LCD, PDP, OLED, etc, in the field of the FPD (Flat Panel Display) and is applicable to models with a variety of specifications.

④ Applicable to the In Line equipment and is produced as a compact size to be used in the cleam room

⑤ The feedback control is possible for the temperature and UV light quantity of the lamp house, and the automatic cooling system is applied.

⑥ Controllable due to perfect interlocking operation with the main equipment, and easy to maintain and repair

Main Specifications