Motivation for Development

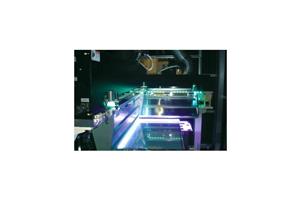

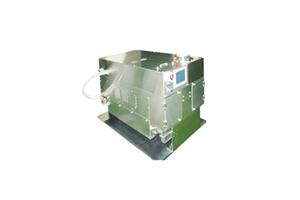

This is a curing machine developed at the request of a Japanese cosmetic container manufacturer and cures the printed portion on the surface of containers. It is used to cure the surface of printed materials as well as cosmetic containers, and the curved surface and inside of general containers, beverage bottles, and electronic parts. It is designed to cure the surface well through uniform irradiation of UV rays on even three-dimensional surface of the product. It is more useful for processing 3D-shape products because their 360-degree front is cured, and given a favorable reception from field workers due to no UV ray leakage.

Main Use : For printing on cosmetic containers and curing processing on the surface of general containers

Product Features

① This equipment is exclusively reserved for temperature-sensitive curved (3D) products, and is available on the market for printing, bonding, etc. of plastic containers, such as PET and PTEF. It required high intensity due to curved shape of products, and the chamber is also to be maintained at a low temperature.

② It adopts the multi-axis exposure method for optical design, and products with 10m/min in line speed usually make up its largest portion.

③ It cuts unnecessary wavelengths that cause side reactions to ink and adhesives and processes products while keeping the processed surface of products at a low temperature (almost room temperature), by using various optical filters.

④ Configured to mount and dismount the lamp easily, and designed to realize mechanical drive characteristics smoothly

⑤ Capable of changing irradiation distance, exposure angle, etc., depending on the types of products, and adopts the tilt-prevention system for the conveyor system

⑥ It is the model that has minimized light leakage and improved safety and is easy to maintain and troubleshoot.

Main Specifications