Motivation for development

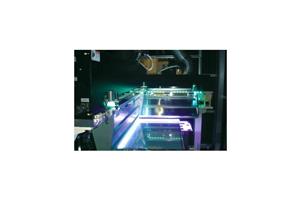

This is a semi-automatic collimated exposure machine for small PCB makers that contains the alignment function.

Use : For PCB- and FPCB-manufacturing process

Product Features

① As a Fine Pattern exposure machine, this equipment is a widely used model to manufacture Lead Frame, EMI Filter, CSP, etc. Its standard panel size is 510 x 610 and the mechanical system is controlled by a PC. Its product-processing conditions adopt the conversation method between the touch screen and M/C.

② The half-collimation angle is 1.5 degrees.

③ It minimizes light leakage, has low noise during the operation, is easy to maintain and troubleshoot, and is a model with improved intensity stability.

④ Alignment standard: 10 ± 3㎛. Based on a two-point edge on a diagonally square to the substrate glass

• 2 CCD Camera FOV = (6.4mmX4.8mm), M/Film Alignment-based (Left, Center, Right) (Option: 4CCD)

• Alignment Mark fixed: (Ø0.5 ~ 1.5) / 2-point move mark: (Ø1 ~ 3) Hole

• Standard pin stand for mask settings (alignment range: Marc tolerance: ± 0.3mm)

⑤ Drive type: for up and down drive, 2-point motor, for right and left drive, 1-point motor, and for reverse drive, toward the lens Using the stepper motor for the matching of X, Y, and Z, Resolving power to drive the upper plate mask-fixing (fixed reference) stage: 2㎛ or below, Amount of movement: ± 5mm

⑥ Mask Film Setting method: Processing the position of the pre-alignment mark with images and setting films manually

• Mask tolerance: ± 0.3mm, Mask Setup Time: 5 minutes

Main Specifications