Motivation for development

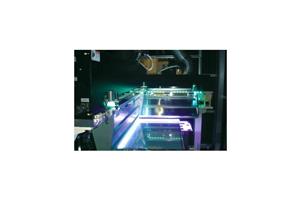

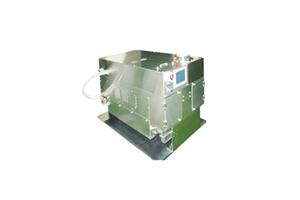

Roll to Roll collimated, single-sided exposure machine developed to suit the process for manufacturing a large capacity FPCB. This equipment is the roll to roll automatic collimated exposure machine for fine patterns, which is inexpensive and has excellent productivity. It is composed of the docking system from which the instrument part and the optical part are separated, is easy to maintain and repair, and allows for quick replacement use through mutual exchange of the instrument part and the optical part like parts. Also, the movement of the equipment is easy, and the interface between equipment is easy and fast

Main Use : for FPCB-manufacturing process

Product Features

① The product which has been developed for FPC’s precision patterns, has 95% or more in beam uniformity, and is processed at 20 to 25㎽/㎠ of UV flux.

② Half-collimation angle is 1.5 degrees or less, and is widely used of mass production with a 30 to 40㎛ resolution.

③ The light source adopts the “single-sided exposure method” using a 5kW Short arc UV Lamp 1 etc., and the temperature in the lamp house/chamber is optimally controlled with the independent feedback system. The product’s processing speed is 3 to 4 panels/ min.

④ Allows for saving the space and very easy application because this is a compact size and the product developed as the structure that can be mounted and dismounted for the whole system.

⑤ It has improved the durability and lifespan due to the use of optical and mechanical filters, minimized light leakage and noise during operation, and improved safety. It is also easy to maintain and troubleshoot.

Main Specifications