ASFLOW SUPERCLEAN PIPE & TUBE

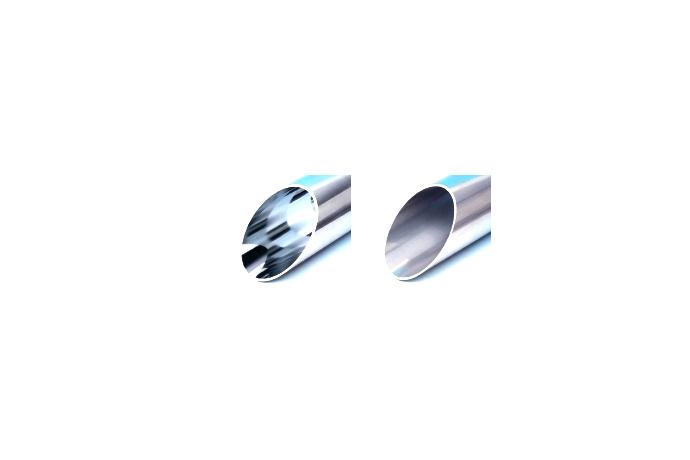

With state of the art EP technology, ASFLOW produces ultra high purity pipe & tube used in semiconductor & aerospace applications.

Manufacturing Process

Grade

ㆍAP – Annealed and Pickled Pipe

ㆍMP – Mechanically Polished Pipe

ㆍBA – Bright Annealed Pipe

ㆍEP – ElectroPolished Pipe

ASFLOW MATERIALS

ㆍSUS 316L Single melt or SUS 316L Double melt is used to meet the stringent requirements of the semiconductor and aerospace industries.

ㆍOur state-of-the-art Pipe & Tube prevent out gassing and improve corrosion resistance while providing excellent compatibility with speciality gases and chemicals.

| Material | Surface | Grade | |

|---|---|---|---|

| Seamless |

SUS316L Single Material[VOD] SUS316L Double Material[VIM+VAR] |

|

EP |

|

BA | ||

| Weled |

SUS 304/316

SUS316L |

|

MP |

|

AP |

ㆍElectropolishing improves surface roughness by selective solution of surface

PIPE SIZE

| PIPE SIZE | OUTERDIAMETEROD[mm] | THICKNESS | LENGTH | |

|---|---|---|---|---|

| T=5S | T=10S | |||

| 8A | 13.8 | 1.2 | 1.65 | 4M[6M] |

| 10A | 17.3 | 1.2 | 1.65 | |

| 15A | 21.7 | 1.65 | 2.1 | |

| 20A | 27.2 | 1.65 | 2.1 | |

| 25A | 34.0 | 1.65 | 2.8 | |

| 32A | 42.7 | 1.65 | 2.8 | |

| 40A | 48.6 | 1.65 | 2.8 | |

| 50A | 60.5 | 1.65 | 2.8 | |

| 65A | 76.3 | 2.1 | 3.0 | |

| 80A | 89.1 | 2.1 | 3.0 | |

| 100A | 114.3 | 2.1 | 3.0 | 4M |

| 125A | 139.8 | 2.8 | 3.4 | |

| 150A | 165.2 | 2.8 | 3.4 | |

| 200A | 216.3 | 2.8 | 4.0 | |

TUBE SIZE

| PIPE SIZE | OUTERDIAMETEROD[mm] | THICKNESST | LENGTH |

|---|---|---|---|

| 1/4″ | 6.35 | 1.0[0.89] | 4M[6M] |

| 3/8″ | 9.53 | 1.0[0.89] | |

| 1/2″ | 12.7 | 1.0, 1.24[1.65] | |

| 3/4″ | 19.05 | 1.65[1.24] | |

| 1″ | 25.4 | 1.65[1.24] | |

| 1 1/4″ | 31.8 | 1.65 | |

| 1 1/2″ | 38.1 | 1.65 | |

| 2″ | 50.8 | 1.65 | |

| 2 1/2″ | 63.5 | 1.65 | |

| 3″ | 76.2 | 1.65 | |

| 4″ | 101.6 | 2.11 | |

| 5″ | 127 | 2.77[3.05] | |

| 6″ | 152.4 | 2.77[3.05] |

Qualty Standard

| Grade | Particle Counting | Oil Content |

|---|---|---|

| AP | Particles larger than 0.30um are less than 5 | ≤ 0.1mg/ft2 |

| MP | Particles larger than 0.10um are less than 5 | ≤ 0.01mg/ft2 |

| BA | Particles larger than 0.10um are less than 5 | ≤ 0.01mg/ft2 |

| EP | Particles larger than 0.10um are less than 1 | ≤ 0.01mg/ft2 |

ㆍInternational Standard ASTM F1394, SEMI F70-0302

Qualty Standard

| Grade | Size[ØOD] | Ra[unich] | Ry[max]:um |

|---|---|---|---|

| AP | ALL | ≤100 | ≤25 |

| MP | 25.4 ≤OD≤267.4 | ≤20 | ≤4.0 |

| BA | 6.35≤OD≤48.6 | ≤15 | ≤3.0 |

| 48.6 ≤OD≤267.4 | ≤20 | ≤4.0 | |

| EP | 6.35≤OD≤48.6 | ≤10 | ≤0.5 |

| 48.6 ≤OD≤267.4 | ≤10 | ≤0.7 |

ㆍSize not shown on this catalog are available at a customer’s request. Please contact us.

Hardness Test

ㆍRequirement : Max HV-196

ㆍInternational Standard SEMI F82-0304

ㆍTest Sample : SUS316LPT Ø25.4mm x 1.65mm

| Measuring Point | X1 | X2 | X3 | X4 | Average |

| Measurement | 168 | 172 | 165 | 162 | 167 |

TUBE & PIPE CAPACITY

| Product | Material | Grade | Size |

|---|---|---|---|

| Seamless | SUS316L (S/M) | BA/EP | 1/4″~100A |

| SUS316L (D/M) | EP | 1/4″~1″ | |

| Seam(welded) | SUS304 | AP/MP | 1/4″~400A |

| SUS316L (D/M) | BA/EP | 1/4″~300A | |

| SUS316L (D/M) | EP | 1/4″~200A |

ㆍSeamless Capacity (per month) 200,000M

ㆍSeam Capacity (per month) 50,000M