|

Outline |

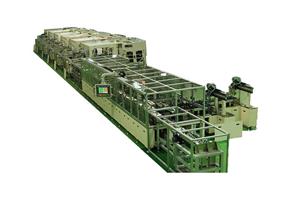

This equipment inserts Cell and Ribbon to perform alignment and Hot air soldering processes for production of Strings connected in series. |

|

|

Specification |

Cell size |

156.1*156.1mm, (2 or 3 bus-bar) |

|

Cell thickness, Cell bowing |

200+_20µm, Less than 2mm |

|

|

Maximum string length |

1900mm, Ribbon edge:15~30mm |

|

|

Distance of cells |

~3mm adjustable |

|

|

Ribbon Width |

For 6” cells:1.5mm, 2.0mm, 2.5mm |

|

|

Number of ribbon per cell |

Two(2) or three(3) bus bar 6 inch cells |

|

|

Throughput |

Up to 600cells/hour with the following materials; |

|

|

Cell magazine loader |

Four(4) cell loading magazines on the loading indexes |

|

|

Alignment |

Visual camera for cell alignment and inspection of chip around the edge of the cell |

|

|

Flux spray |

Non contact flux spray nozzle applicator |

|

|

Ribbon Applicator |

Spool, Stretching, Cutting, Stress-Release form Transfer |

|

|

Soldering |

1. Preheating |

|

|

String conveyor |

Total Five(5) stainless steel belts |

|

|

Operation |

PLC & Touch Panel |

|

|

Utilities |

AC 220V, 3phase, 60Hz |

|

|

Room condition |

Temperature: 25℃±5℃, Humidity: 40-50% |

|

|

Flow direction |

Left to Right or Right to Left |

|

JINWOO ENGINEERING

Manufacturer of Automobile facility, Super precision welding facility, Measuring inspection facility, Electron gun production facility

| Name |

Tabber&Stringer |

| Series | Solar |

Product Description

Products of JINWOO ENGINEERING

-

Automative Assembly

-

Torque Angle Sensor

Automative Assembly

-

Yoke Ass`y Machine

Automative Assembly

-

Ignition Coil

Automative Assembly

-

Battery

-

Can Cap Welder

Battery

-

Auto Stacker

Battery

-

Tab Welder

Battery

-

IT Glass

-

Scriber

IT Glass

-

CNC Edge Grinder

IT Glass

-

Light Bulb

-

Halogen Lamp

Light Bulb

H8/9/11/16

-

Halogen Lamp

Light Bulb

H7

-

Optic Film

-

Film Laminator#1

Optic Film

-

Film Laminator#2

Optic Film

-

Film Auto Cutter

Optic Film

-

Plasma Application

-

Wiring Thin Film Coater For TSP

Plasma Application

-

ITO Coater

Plasma Application

-

AL Coater

Plasma Application

-

AF Coater

Plasma Application

-

ARAF Coater

Plasma Application

-

Solar

-

Tabber&Stringer

Solar

-

Layup & Bussing

Solar