|

Outline |

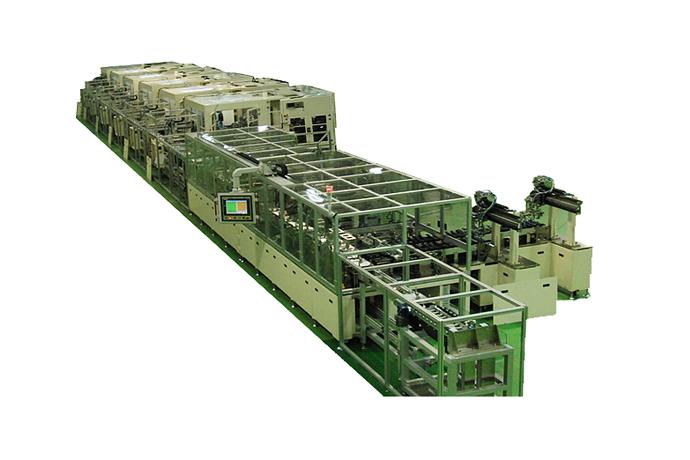

This equipment cross-stacks positive/negative electrodes cut during Pouch Type EV Battery manufacturing process, by alternating with the Separator in sequence. |

|

|

Specification |

Dimension |

3200 * 2000 * 2000 |

|

Jelly Roll Size |

Max 157 * 267 |

|

|

Jelly Roll Thickness |

Max 13.8 |

|

|

Cycle Time |

1.5 sec / 1 electrode [Equipment throughput determined by total number of stacks] |

|

|

Electrode Magazine Loader |

2 Magazines each for positive/ negative electrodes [Shuttle Type] |

|

|

Alignment |

Visual camera for cell alignment and inspection of chip around the edge of the electrodes |

|

|

High Speed Movement |

Linear Motor [Magnetic Core] |

|

|

Separator Feeding |

Tension & EPC Control |

|

|

Separator finish |

Edge Bonding Type – Type 1 Tape |

|

JINWOO ENGINEERING

Manufacturer of Automobile facility, Super precision welding facility, Measuring inspection facility, Electron gun production facility

| Name |

Auto Stacker |

| Series | Battery |

Product Description

Products of JINWOO ENGINEERING

-

Automative Assembly

-

Torque Angle Sensor

Automative Assembly

-

Yoke Ass`y Machine

Automative Assembly

-

Ignition Coil

Automative Assembly

-

Battery

-

Can Cap Welder

Battery

-

Auto Stacker

Battery

-

Tab Welder

Battery

-

IT Glass

-

Scriber

IT Glass

-

CNC Edge Grinder

IT Glass

-

Light Bulb

-

Halogen Lamp

Light Bulb

H8/9/11/16

-

Halogen Lamp

Light Bulb

H7

-

Optic Film

-

Film Laminator#1

Optic Film

-

Film Laminator#2

Optic Film

-

Film Auto Cutter

Optic Film

-

Plasma Application

-

Wiring Thin Film Coater For TSP

Plasma Application

-

ITO Coater

Plasma Application

-

AL Coater

Plasma Application

-

AF Coater

Plasma Application

-

ARAF Coater

Plasma Application

-

Solar

-

Tabber&Stringer

Solar

-

Layup & Bussing

Solar