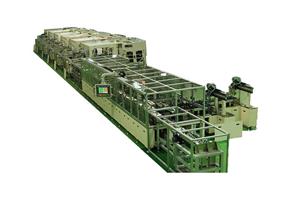

ARAF Coater

Sputter is used for multi-layer Array Plating of Si to add the Anti Reflect function. It is intended for Thin Plating of the Anti Finger liquid chemical on Glass surface of the Rabital Target.

The equipment is used to reduce Glass upper surface and reflection, improve Transmissivity, and prevent scratches caused by finger prints.

It is also used to form AR & AF Plating on tempered glasses such as for Smart Phones & Tablet PC.

|

Features |

|||

|

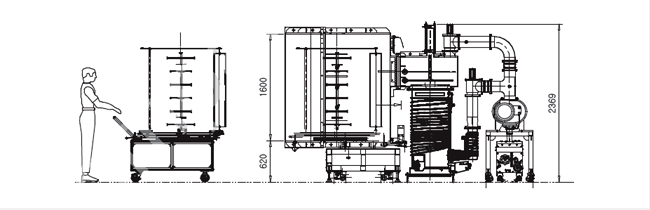

Size |

High4,500 x 3,800 x 2369mm |

||

|

Gross Weight |

4,500kg |

||

|

Equipment Specification |

Compressed Air |

Pressure |

Min/Max, 6/8Kgf/㎠ |

|

Usage |

20ℓ/min |

||

|

Cooling Water |

Air cooling type detachable |

25 RT, 2kgf/㎠, 5-25℃ |

|

|

Tank capacity |

350ℓ |

||

|

Utility |

Electric Power |

380V 3P 4W, 115kW |

|

|

Main distributing board : 175A_3 phase |

|||

|

Power cable : 60SQ 3phase+Ground 16SQ _Single phase |

|||

|

150 |

|||

|

Specification |

||

|

Substrate & Carrier |

Substrate material |

Tempered Glass |

|

Substrate size |

[10.1" std.] 192ea / 1time process |

|

|

Tact Time |

Less than 80 Min/ 1 time process |

|

|

Vacuum |

Ultimate pressure |

5.0 x 10-5 torr↓ |

|

No Load (No specimen) |

Vacuum exhaust speed |

6min ↓ (ATM→ 5x10-2 torr) |

|

Status |

20min ↓ (ATM→ 5.0x10-5 torr) |

|

|

Main |

Chamber |

Φ1,600*H1600 |

|

Chamber |

Φ1,600*H1600 |

|

|

Source |

Sputter+ Evaporation |

|

|

Work Jig |

Φ300 * 12 Axis |

|

|

Pump |

Diffusion Pump |

20” 1 Set |

|

Rotary & Booster Pump |

E2M275 & EH2600 |

|

|

Vacuum Level |

5*10-5torr |

|

|

Option |

Chiller |

25RT |

|

Poly Cold |

200,000L/Sec |

|

|

Layout |

|

|

Comparison |

|||||||

|

Description |

AR AF-1600 Sputter ( Φ1,600 ) |

E-Beam AF ( Φ2,050 ) |

|||||

|

Capa |

Batch Time |

80min |

45min |

||||

|

Glass Size |

4” |

7” |

10.1” |

4” |

7” |

10.1” |

|

|

1 Batch |

1,080 |

320 |

192 |

260 |

99 |

35 |

|

|

Day [22Hr] |

17,280 |

5,120 |

3,072 |

8,580 |

3,267 |

1,155 |

|

|

Month [26Day] |

449,280 |

133,120 |

79,872 |

223,080 |

84,942 |

30,030 |

|

|

Deposition Temp |

25~35℃ |

80℃ or higher |

|||||

|

Target |

Rotative & Orbital Magazine 12ea |

Dome |

|||||