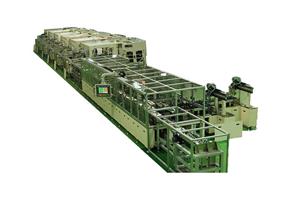

AF Coater

This equipment deposits Fluorine Chemical Compound on to the product surface using PeCVD & Thermal Evaporation method in addition to supplementing the adhesive Anti-Finger function.

It is intended for AF Plating on tempered glasses used on Smart Phones & Tablet PCs.

|

Features |

|||

|

1 |

High |

User Friendly |

1. Rotative & Orbital Load/Unloading |

|

Production Capacity |

4~6 times larger than E-Beam [Size] |

||

|

2 |

Low |

Chamber Size |

3/4 of E-Beam |

|

Temp (25~35˚) |

80℃ or higher than E-Beam |

||

|

Operating Cost |

Lower Vacuum Pumping than E-Beam |

||

|

Coefficient Of Friction |

|||

|

Specification |

||

|

Works Space |

L4500*D6500*H2700 |

|

|

Weight |

4.5 Tons |

|

|

Main |

Chamber |

Φ1,600*H1600 |

|

Source |

PeCVD+ Evaporation |

|

|

Work Jig |

Φ300 * 12 Axis |

|

|

Pump |

Diffusion Pump |

20” 1 Set |

|

Rotary & Booster Pump |

E2M275 & EH2600 |

|

|

Vacuum Level |

5*10-5torr |

|

|

Option |

Chiller |

15RT |

|

Poly Coldp |

100,000L/Sec |

|

|

Layout |

|

|

Comparison |

|||||||

|

Wise AF-1600 PeCVD ( Φ1,600 ) |

E-Beam AF ( Φ2,050 ) |

||||||

|

Capa |

Batch Time |

40min |

45min |

||||

|

Glass Size |

4” |

7” |

10.1” |

4” |

7” |

10.1” |

|

|

1 Batch |

1,080 |

320 |

192 |

260 |

99 |

135 |

|

|

Day [22Hr] |

35,640 |

10,560 |

6,336 |

8,580 |

3,267 |

1,155 |

|

|

Month [26Day] |

926,640 |

274,560 |

164,736 |

223,080 |

84,942 |

30,030 |

|

|

Deposition Temp |

25~35℃ |

80℃ or higher |

|||||

|

Target |

Rotative & Orbital Magazine 12ea |

Dome |

|||||