Features

· Excellent interior pressure resistance & impact resistance

∙ Excellent durability & non-flammability

∙ Prevention of resonance phenomenon by cement filling

∙ Suitable for high-load operation zone due to maximization of load

∙ Recycling allowed after replacement only of finish materials upon transfer & disposal

∙ Product certified for BS EN 12825 Class 6/A/3/2 of Europe

Usage

· Plant, power plant, disaster prevention center, machine room, data processing room

∙ Various equipment rooms, vessel & marine plants

∙ Other zones with frequent moving of high loads/heavy objects

Finishing

· Conductive Tile

∙ Deluxe Tile

∙ PVC Vinyl Sheet

View Blueprints

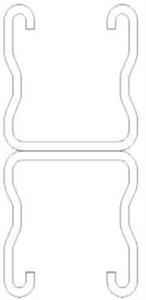

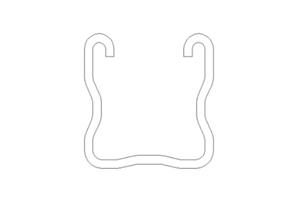

| Panel Dimension | Panel Thickness | Panel Weight | Installation Weight | Upper Plate | Lower Plate | Coating |

| 600x600mm | 35T | 18kg/sheet | 54kg/m2 | Hot-rolled steel plate | Cold-rollered steel plate | Electrostatic powder coating |

BS EN 12825 Test

| Working Load | Ultimate Load | Deflection of less than 2.5mm | Safety Factor | Dimensional tolerance classification | ||

| 4kN | 25kN | Class 6 | 2.31mm | Class A | 3 | Class 2 |

| Dynamic Load Test | ||||

| Test Item | System Height | Steel Indentor Mass | Drop Height | Observation |

| Hard Body Impact | 600mm | 4.5kg | 600mm | Sample did not collapse No visible damage was observed |

| Soft Body Impact | 40kg | 1,000mm | ||

| Permanent Deformation at Weakest Point | ||||

| Location of indentor | Finished floor height | Measured residual deflection | Imposed Load | Result |

| Panel center of edge | 600mm | 0.39 | 4kN working load | Pass |

| Pedestal Vertical Load Test | |||

| Finished floor height | Imposed Load | Observation | Result |

| 600mm | 16kN | The pedestal did not collapse, distorted or damaged | Pass |