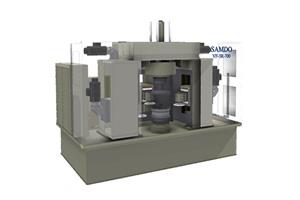

The characteristics of SF1-60

- High productivity

- It is possible to prepare for next process faster by making preparation process speed faster and molding process speed slower in precision part manufacturing

- It is possible to adopt automation device, progressive manufacturing with long feed pitch or robot by making transfer time (standby time) longer

- High degree of precision

- Bottom dead point degree of precision is always kept at 5 micron by adopting special devices developed by Samdo Press

- Realized 1 micron bottom dead point degree of precision by feedback control of servo motor through linear scale

- Low noise

- Noise generated during driving power connection has been removed by not using clutch break

- It is possible to decrease noise while keeping productivity since servo press can make only the moment of product punching to work at low speed

- Varying the stroke length

- Product with complex manufacturing requirement can be easily manufactured by varying stroke

- Control molding speed to fit with product requiring difficult manufacturing

- Since molding speed can be controlled, high precision manufacturing by bottom dead point stop and complex manufacturing while stopped have been realized

SF1-60 Specification

| Item | unit | SF1 - 60 | ||

|---|---|---|---|---|

| Capacity | TON | 60 | ||

| Stroke | mm | 60 | ||

| S. P. M | S.P.M | 50 ~ 150 | ||

| Die Height | mm | 300 | ||

| Slide Adjustment | mm | 50 | ||

| Slide Area | mm | 520 x 310 | ||

| Bolster Area | mm | 860 x 520 | ||