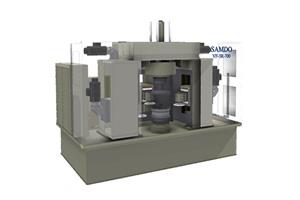

The characteristics of SDH SERIES

- Keep high degree of precision, high hardness and high performance by applying casting type frame which has optimum hardness designed by computer simulation

- Minimized vibration and improved durability of machine's driving part by designing by computer dynamic analysis and making driving axis by special steel

- Kept degree of precision and extended the life of mold by adopting special bearing on slide guide plane

- Minimized vibration and noise while improving durability by adopting air spring

- Shortened mold setting time by adopting die height counter and slide automatic-controlling motor

SDH SERIES Specification

| Item / Model | Unit | SDH-35 | SDH-50 | |||||

|---|---|---|---|---|---|---|---|---|

| Capacity | TON | 35 | 50 | |||||

| Stroke Length | mm | 20 | 30 | 40 | 20 | 30 | 50 | |

| Stroke Per Minute | S.P.M | 150~ | 150~ | |||||

| 350 | 300 | 250 | 300 | 250 | 200 | |||

| Die Height | mm | 250 | 245 | 240 | 280 | 275 | 265 | |

| Slide Adjustment | mm | 40 | 50 | |||||

| Shank Hole | mm | Φ50 | Φ50 | |||||

| Side Area | mm | 420×250 | 520×310 | |||||

| Bolster Area | mm | 680×380 | 800×500 | |||||

| Bolster Thickness | mm | 105 | 120 | |||||

| Main Motor | Kw×p | 5.5×4 | 7.5×4 | |||||

| Slide-Adjust Motor | W×p | 150×4 | 200×4 | |||||

| Air Pressure | ㎏/㎠ | 5 | 5 | |||||

| Weight(Approx.) | TON | 3.5 | 6.0 | |||||

| Major Dimensions | mm | 1200×1120×2070 | 1500×1400×2450 | |||||