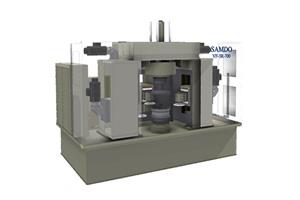

The characteristics of SDH-60G

- This press is applied of eccentric gear on its driving mechanism to realize low speed of slide at the product molding section

- Improved degree of precision by low speed at bottom dead point

- Extended life of mold by decreasing noise and impact during manufacturing

- Adopted high degree of precision linear bearing on slide guide

- Increased durability by decreasing error in being parallel and vibration when slide moves up and down

- Minimized impact on eccentric load by location characteristic

- The user-friendly electric-driven/manual slide control device is capable of fine adjustment down to 0.01mm

- Screw tolerance gap is kept at "zero" by adopting hydraulic screw fixing device

- High torque clutch break has been developed by self for use

- Reliability is warranted by measuring static/dynamic degree of precision when shipping

SDH-G SpecificationItem unit SDH-60G SDH-80G SDH-110G SDH-150G SDH-200G Capacity Ton 60 80 110 150 200 Stroke mm 60 60 60 60 80 S. P. M S.P.M 200 180 150 130 100 Die Height mm 320 350 400 400 400 Slide Adjustment mm 50 70 70 70 70 Slide Area mm 520 x 310 700 x 550 800 x 480 900 x 500 1000 x 600 Bolster Area mm 870 x 520 900 x 600 1100 x 700 1200 x 700 1300 x 800