A Center Grinding Machine precisely grinds the outer daimeter of cylindrical material and is used variously across all industrial sectors including automobile, electricity, electronics and appliances. This machine does not support the center of processed goods and develops the grinding process which is different from a cylindrical grinder.

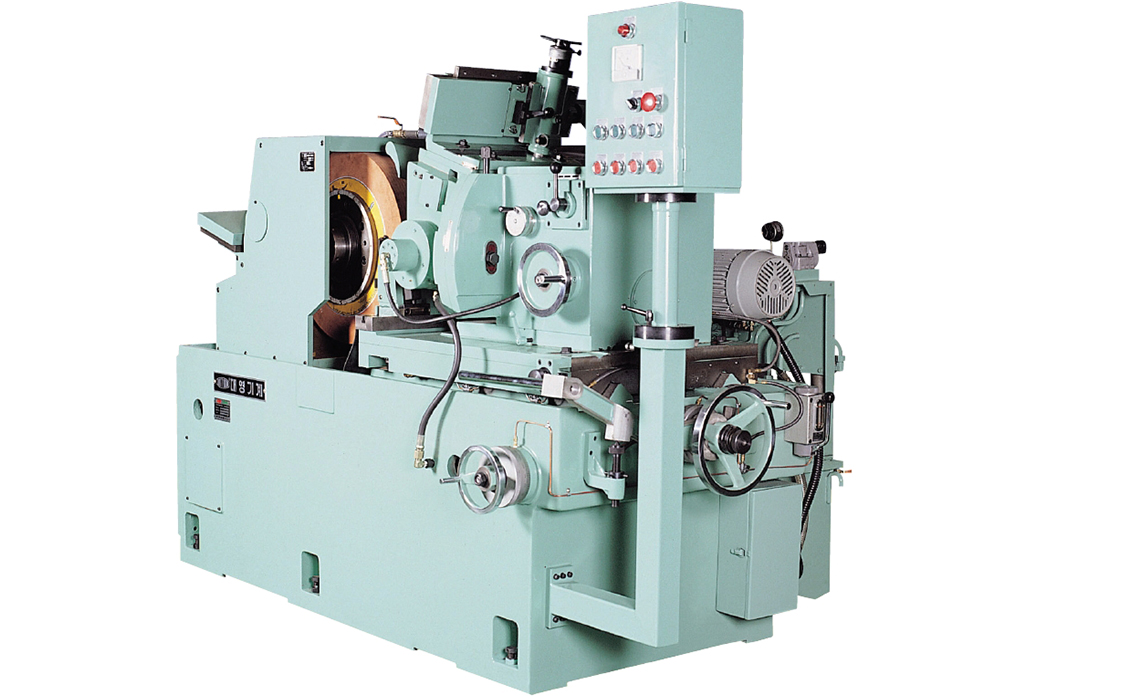

CENTERLESS GRINDING MACHINE

Spindle and Bearing

- Raises axial stiffness by supporting the grinding wheel with workhead and 3 bearings at shaft ends.

- Use of a hydraulic dynamic bearing to enhance high bearing stiffness and vibration reduction effect, showing excellence in powerful grinding and precision grinding.

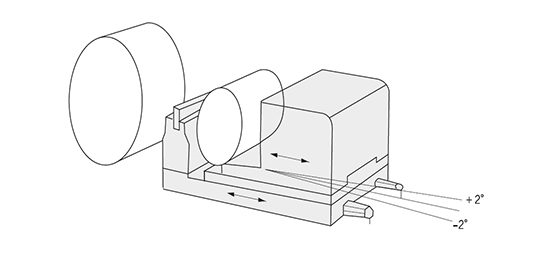

Feeding device and horizontal spin device

- Lower feeding device and upper feeding device performing respectively the feeding of the grinding stand and regulating wheel.

- Precise feed adjustment is enabled by cross feed of a feeding device, a minute feeding handle and the back flash adjustment device of a feeding screw.

- The lower slide sideway maintains long-term precision by being precisely produced by multiple profiles.

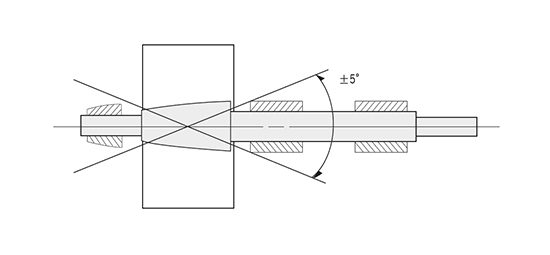

- A regulating wheel spin device capable of rotating up to ±5 degrees horizontally is used to adjust a level of parallel on the regulating wheel axis and the taper angle (adjustment during the operation also possible)

Inversion device of a regulating wheel

- Enables the regulating wheel to rotate up to ±5 degrees, which broadens ranges of the speed at which work pieces pass.

- Very useful for setting the reference position when working during the stoppage.

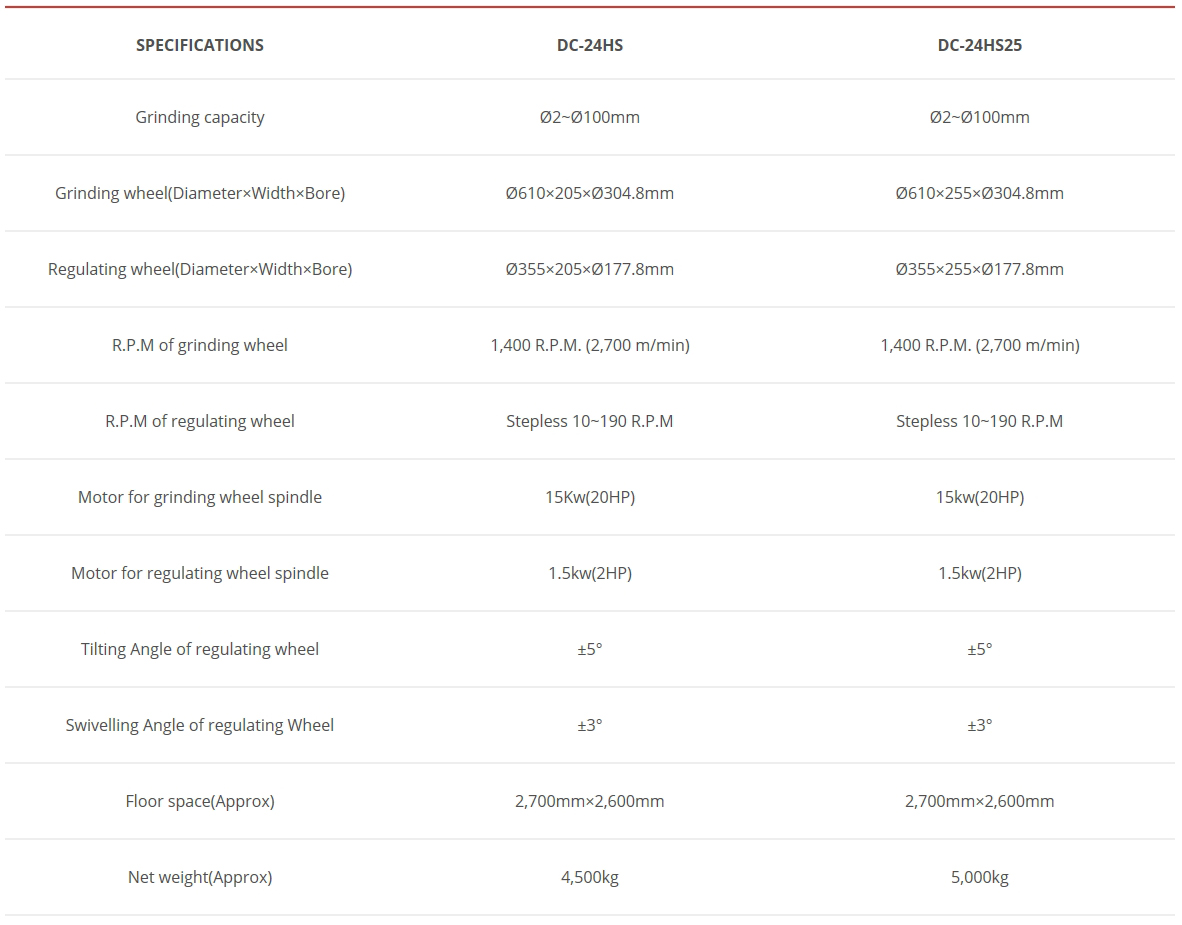

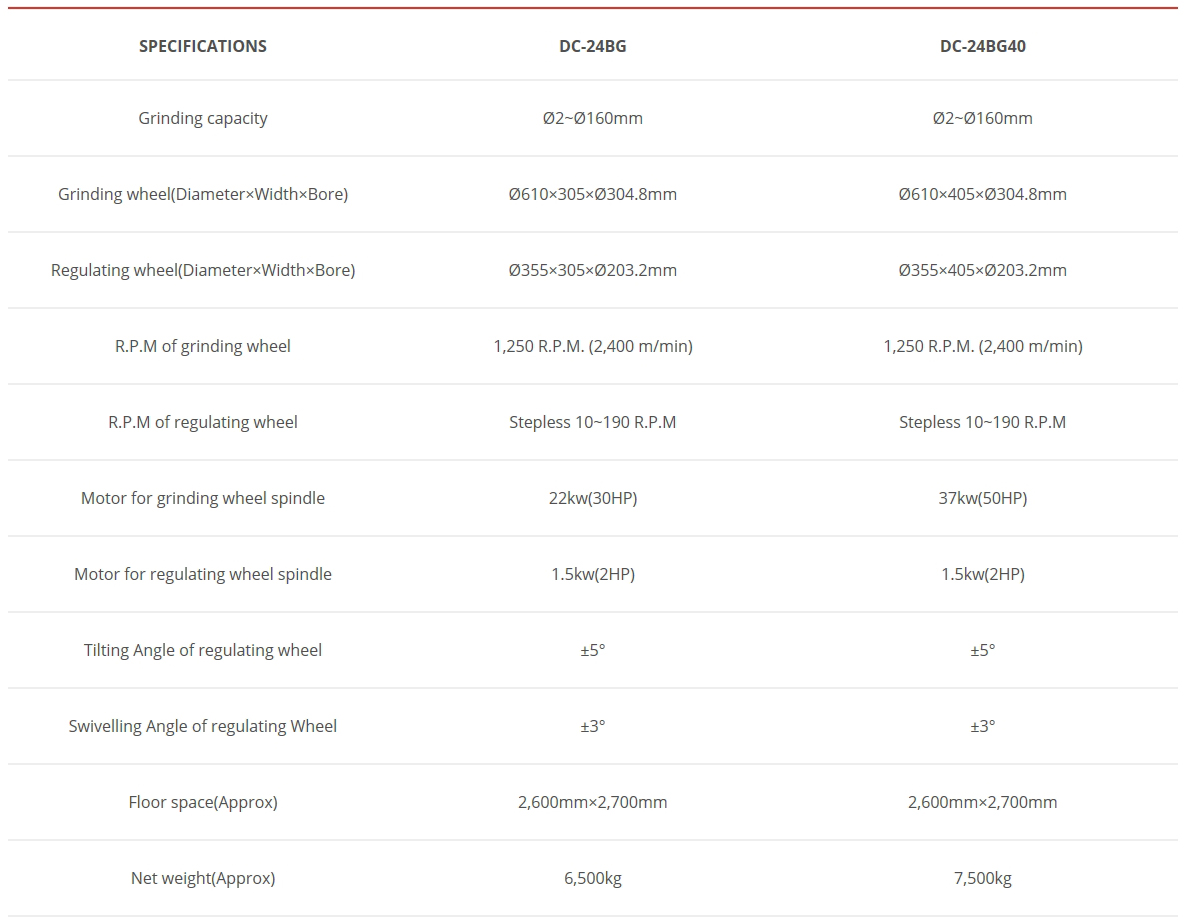

Items | Specifications |

Grinding capacity (Special) | Ø1mm~Ø40mm(Ø25mm~Ø100mm) |

Grinding wheel(Diameter×Width×Bore) | Ø455×205×Ø228.6mm |

Regulating wheek(Diameter×Width×Bore) | Ø255×205×Ø111.2mm |

R.P.M of grinding wheel | 1,500 R.P.M. (2,000 m/min) |

R.P.M of regulating wheel | 10~308 R.P.M. (Stepless) |

Motor for grinding wheel spindle | Standard 11kw(15HP)×4P |

Motor for regulating wheel spindle | 1.5kw(2HP)×4P |

Tilting angle of regulanting wheel | ±5° |

Swivelling angle of regulanting wheel | ±2° |

Floor space | 2,300mm×2,200mm |

Net weight | 3,000kg |

HYDROSTATIC BEARING TYPE

Features

- Super-precision, high-speed grinding machines.

- Use of hydrostatic bearings.

- High-speed grinding- enhanced grinding wheel speed of 2,700m/min.

- Precision grinding- excellent bearing stiffness and high level of rotation.

- Heavy grinding- excellent axial stiffness to be effective also for heavy grinding.

Use of hydrostatic bearings

- When oil under fixed pressure is supplied to the oil pocket of a hydrostatic bearing arrayed around the shaft, the shaft is positioned at the center of the axis by the oil pressure.

- Excellent in ability to maintaining the axis at the center against the external load

- Powerful axial stiffness and excellent degree of rotation.

- No shaft wear because shaft and bearing do not come into contact.

Dual Support Spindle System

Features

- High-precision, high-efficiency, heavy cutting large-scale centerless grinding machine.

- Bed of super-stiffness structure.

- Grinding adjustment, a complete support of both axis.

- Assembling the special precision taper roller bearing and angular ball bearing under optimal pre-pressure.

- Guarantees high precision and long life by adopting a forced spray type of lubrication.

- Enables a precise feeding also for heavy cutting with the use of powerful precision ball screws at the loser slide.

POWERFUL AND USER FRIENDLY CNC CONTROL SYSTEM

Features

- CNC Control System can be applied to each Centerless Grinding Machine.

- CNC control system programmed to be primarily convenient for operation.

- Easy automation such as precision grinding, workpiece transfer, work transfer.

- Applies to detailed functions such as lower slide feeding, upper slide feeding, GW dressing, RW dressing, swivel device feed, and workpiece loading automatic device.

- Performs various types of grinding work, that is penetration, stop work cycle conversion, workpiece data modifications and change of grinding conditions.

FEEDING DIAGRAM