Features of seeding roll

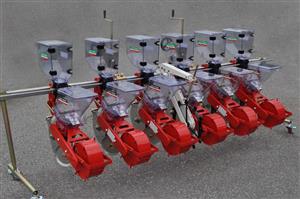

- 1/2/3 row types and zig zag processing (special roll & coating seeding roll)

- 1/2/3 row types and zig zag processing (special roll & coating seeding roll)

- Electrostatic-handling processed

- CNC (there-dimensional precision processing)

Method to choose a proper seeding roll

| Name of roll | YYJ | YK | X | YJ | F | FJ | MJ | L | Q | R | G | C | AA | A |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External diameter | 3 | 3.5 | 4 | 5 | 5 | 6 | 6.5 | 7 | 8 | 9 | 9 | 11 | 12 | 13.5 |

Seed name/ Seeding roll standards

| Seed name | Seeding roll standards | Seed name | Seeding roll standards |

|---|---|---|---|

| Bok choy, Indian mustard, vitamin | YYJ-12 | Chives, chamnamul | A-6 |

| Winter-grown cabbage | YJ-12 | Sorghum | R-12 |

| Crown daisy | MJ-12 | Soybean | N-6 |

| Spinach | F-12 | Wheat, buckwheat | C-12 |

| Carrot | M-12 | Rice, barley | AA-6 |

| Young radish | FJ-12 | Sesame | X-8 |

| Radish | Q-4 | Sweet corn | S-4 |

| Curled mallow | YK-12 | Corn | U-4 |

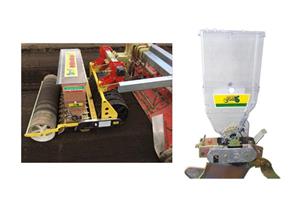

Choosing a roll based on a hopper cover

Pour some seeds into a cover, spread them evenly and choose a suitable groove standard.

Development of seeding roll made of electrostatic handling material

Seeding roll > Discharge of seeds (blocking a brush) >

Discharge of static electricity (discharged to the ground though a plough) > Accurate amount of and distance between seeds

| Conductivity test (discharge of static electricity) | Constant temperature heat treatment (stress removal in the rainy season) |

|

|

Various way of processing even quality of seeding rolls through using CNC milling machine