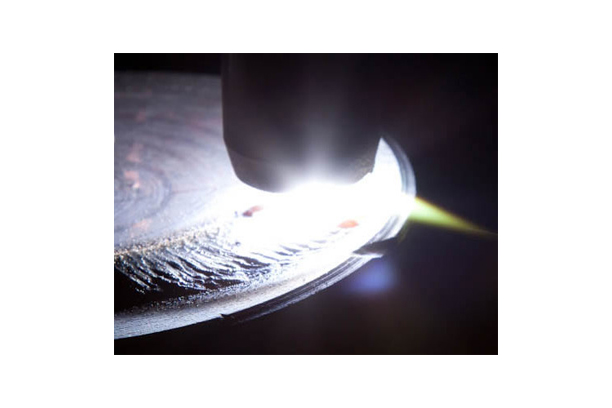

PTA Welding Powders

The PTA (Plasma Transferred Arc) process welds a metallic coating material in powder form to a substrate to produce a hard, wear-resistant coating that is metallurgically bonded to the substrate. The powder is injected into the stream of plasma gas, depositing it onto the workpiece. Wirh PTA process the dilution with the substrate can be controlled as low as 5%.

Nickel Based Powders

Product Code | Hardness | Alloy Composition |

9333 | 30-35 HRC | Ni Cr5.6 B1.2 Si3.0 C0.25 Fe2.5 Al1.2 |

9325 | 20-25 HRC | Ni Cr3.3 B1.1 Si3.1 C0.15 Fe2.2 Al0.3 |

9029 | 33-37 HRC | Ni Cr5.7 B1.0 Si4.7 C0.32 Fe1.6 |

9062 | 57-62 HRC | Ni Cr15.5 B2.9 Si4.3 C0.7 Fe4.2 |

9056 | 52-58 HRC | Ni Cr13.5 B2.8 Si4 C0.55 Fe3.9 |

9053 | 47-53 HRC | Ni Cr12.5 B2.3 Si3.3 C0.5 Fe3.9 |

9033 | 30-35 HRC | Ni Cr8 B1.5 Si3.6 C0.32 Fe2.6 |

9045 | 36-40 HRC | Ni Cr10.3 B2 Si3.2 C0.38 Fe2.4 |

9238 | 36-40 HRC | Ni B2.1 Si3 |

9249 | 48-52 HRC | Ni B3 Si3 |

9265 |

| Ni Cr21.5 Fe0.35 Mo9 Nb3.5 Mn0.5 (Inconel 625) |

Cobalt Based

Product Code | Hardness | Alloy Composition |

42001 | 53-58 HRC | Co Cr30 C2.5 W12 Mo<1 Ni<2 Si Fe Mn |

42006 | 40-44 HRC | Co Cr28.5 C1.1 W4.4 Mo<1 Ni<2 Si Fe Mn |

42006H | 40-46 HRC | Co Cr29 C1.2 W5.2 Mo<1 Ni<2 Si Fe Mn |

42012 | 47-51 HRC | Co Cr28.5 C1.4 W8 Mo<1 Ni<2 Si Fe Mn |

42021 | 28-40 HRC | Co Cr27 C0.25 Mo5.5 Ni2.6 Si Fe Mn |

42000F | 42-46 HRC | Co Cr26 C1.75 W12 Mo<1 Ni22.5 Si Fe Mn |

Iron Based

Product Code | Hardness | Alloy Composition |

304L | <200 HV | Fe Cr18 C<0.04 Si0.5 Ni11 Mn1.3 |

316L | <200 HV | Fe Cr17 C0.02 Si0.8 Ni13 Mn1.5 Mo2.2 |

410 |

| Fe Cr12.5 C0.12 Si0.3 |

420 |

| Fe Cr13 C0.2 Si0.5 Mn0.5 |

* Hardness values are according to heat treatment. ** Other alloy compositions are available.

WC-Ni Alloy Matrix Powder for PTA Welding

Product Code | Nickel Matrix | WC |

15550 | 55 HRC powder 50% | WC-Cast carbide 50% |

15560 | 55 HRC powder 40% | WC-Cast carbide 60% |

15660 | 60 HRC powder 40% | WC-Cast carbide 60% |

15760 | 55 HRC powder 40% | WC-spherical 60% |

* Other or customer specific blends are available.

[ Partical size ] Equipment specific particle size distribution available

* 44 - 125 µm

* 53 - 150 µm

* 63 - 210 µm