Flux additive

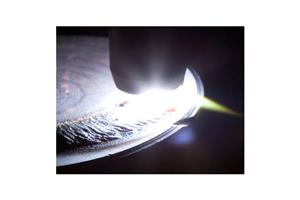

Aluminum The oil component on the surface of the processed product inhibits the flux coating ability and adversely affects the brazing characteristics,The use of this flux additive prevents the deterioration of the brazing property due to residual oil.

Generally, residues on the aluminum surface must be removed through a process such as fine washing or degreasing, Flux additives enhance the flux ability by emulsifying the surface oil components and show a clean appearance after brazing.

Flux additive features

- Improved flux applicability without washing and degreasing process

- Aluminum product helps pyrolysis of surface residue

- Neutral product is not reactive with Aluminum Flux

- Improvement of brazing property due to improvement of coating ability of Aluminum Flux

- Appearance of product after brazing is clear due to increase of dispersion, permeability and diffusion of aluminum flux

Disadvantages of Flux Additives

- As a water-soluble product, keep in mind freezing in winter

- If the oil on the surface of the aluminum product is excessive, a water separator is needed

Packing and specifications

◊ 200 KG Drum

◊ 20 Liter Pail / 20 KG

SPECIFICATION

Properties | Appearance | Oder | pH | Melting Temp. (℃) | Specific Gravity | Base |

HNM-100 | Clear White | No | 7.0 ± 0.5 | 100 ~ 300 | 1.005 ± 0.05 | Water |

HNM-200 | Clear White | No | N/A | 100 ~ 300 | N/A | Water |

HNM-104 | Clear White | No | 6.5 ± 1 | 100 ~ 300 | 1.010 ± 0.02 | Water |