Description

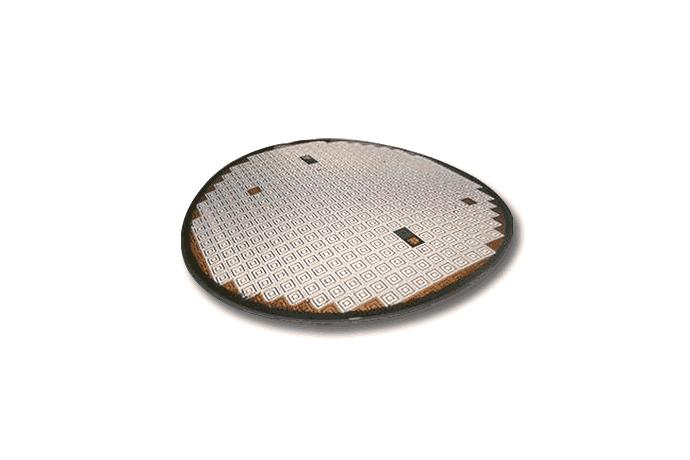

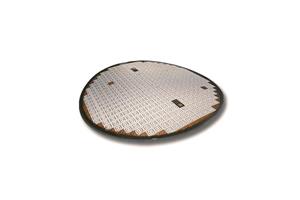

On a semiconductor chip after RDL.

Fan-out structure : Some of solder balls are attached to a substrate outside of a semiconductor chip after RDL.

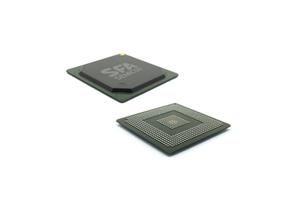

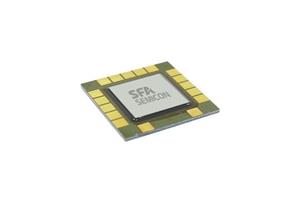

The process of molding the molding compound resin should be performed for Re-distribution layer which is expanded outside of chip. Additional processes for molded layer requires and turn around time is increased. The fan-out package with EMC is consequently warped due to big CTE difference after molding and package crack is generated at the interface among four different materials (Passivation, EMC Cu and Die)

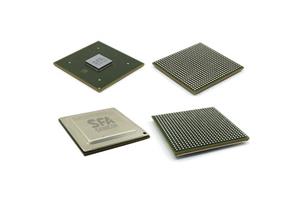

Application

ㆍMobile phones (highest volume application)

ㆍDigital cameras and camcorders

ㆍMP3 players / Watch modules

ㆍLaptop and tablet computers / Medical

ㆍAutomotive

ㆍWearable electronics

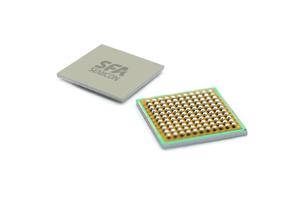

Feature

ㆍReduction of TAT time with skipping WSS process.

ㆍMFG cost down & warpage improvement through using low cure polymer

ㆍNo EMC resin particle issue at sputtering process

ㆍImproved lithography techniques to compensate die shift generated at die mount process

ㆍHigh reliability performance of large sized FO-WLP