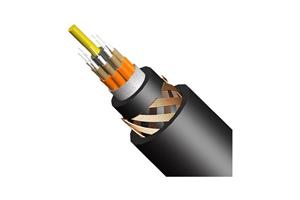

Cables are a key component of wind power generators. The cable running from the generator at the top of the structure to the ground must have enough strength and flexibility to withstand the powerful torsional stresses placed on it as the generator rotates according to wind flow. After many years of research, LS Cable & System has developed both low and high voltage products that have a lifecycle of more than thirty years and can operate in temperatures ranging from -40℃ to 90℃. According to customer needs, we provide services such as cutting and pre-fabrication of connecting materials.

Types and purposes

• MV power cables (Torsion / Fixed)

- 3.6/6kV~20/35kV, excellent torsional resistance, metallic or non-metallic screen versions are available

- 3 cores + 3 earth cores, Tinned copper/ EPR/ Halogen-free XL-EVA

- 40℃ to 90℃, Halogen-free, oil resistant, low smoke, FT4, etc.

- Heat-shrinkable MV terminations available

• LV power cables (Torsion / Fixed)

- Nacelle/loop cables: 0.6/1kV, -55~180℃, EPR/CPE, EPR/XLEVA, silicone/PUR vanished braid, torsion resistant

- Tower cables: 0.6/1kV~1.8/3kV, halogen-free, oil resistant, UV resistance, FT4, etc.

• Control cables

- Nacelle/loop/tower cables: (Un)shielded, 300/500V~0.6/1kV, halogen-free, oil resistance, UV resistance, flame retardant

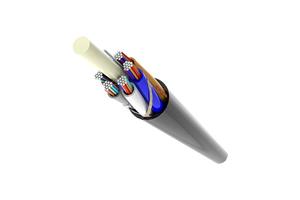

• Communication cables

- Nacelle cable: CAN BUS, PROFIBUS, copper, optical or hybrid (POF + copper cable)

- Loop/tower cable: S_FTP cable, HCS cable, polyurethane sheath, PO, etc.