As the demands for high-voltage, high-output and large-capacity motors, are increasing, the round wire, a type of general magnet wire, has reached a limit in improving the space factor for improving efficiency. To provide a greater space factor than the round wire, the necessity of the flat and rectangular wire increased, and its applications are gradually increasing to include the limited flat and rectangular wire, used in existing large-capacity generators, drive motors for environment-friendly cars (traction motors), high-output alternators, various extra-high-voltage motors and drive motors for high-speed trains (traction motors).

Types and purposes

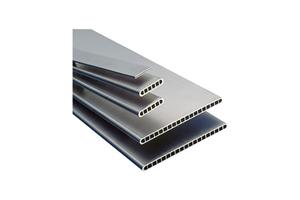

• Coated flat and rectangular wire (flat & fine flat wire)

- Generators for automobiles (alternators)

- Drive motors for electric vehicles (traction motors)

- Air-conditioner compressors for automobiles

- ISG motors for hybrid vehicles

- Special motors for the military

Generators for unmanned motorcars

Radar drive motors unmanned reconnaissance vehicles

In-wheel motors for military motorcars

- Others

Drive motors for electric airplanes

Drive motors for electric ships

• Taping flat and rectangular wire (wrapped flat wire)

- Drive motors for high-speed trains (traction motor)

- High-voltage, high-heat-resistant generators

- Extra-large generators

Thermoelectric power plant

Nuclear power plants

- Large industrial motors and generators

Benefits

The flat and rectangular wire (flat & wrapped wires) have been used mostly in large industrial generators, but its scope of application has been gradually expanded recently, and now it is recognized as the best means of increasing the space factor to improve the efficiency of motors. It is used in various motors for automobiles that required high efficiency, and particularly it is used in most drive motors of environment-friendly cars like electric vehicles (EV) and hybrid vehicles (HEV), and as it is consistently used in driver motors for high-speed trains, wind power generators and extra-large generator that require high heat resistance and high voltage, its scope of application is expected to be expanded rapidly.

• Applied conductor: Copper (ETP, OFC)

• Size (cross-section):

Flat Wire 1.0㎟ ~ 15.0㎟, Wrapped Wire 10㎟ ~ 50㎟

Main functions

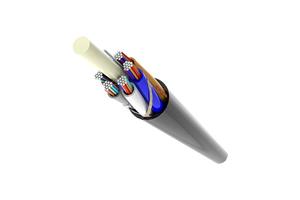

• It is possible to secure insulation performance during complicated forming and bending:

a high modulus of elongation and insulation thickness (Max. 80㎛)

• Optimized for high voltage and, high heat resistance: anti-surge and heat-resistance 240℃ Grade

• High edge coverage: Minimizing conductor resistance and improving output using the optimal edge value (R)

• Diverse insulation performances: Polyimide, Glass Yarn, Mica, Nomex, etc.