According to increasingly stringent global regulations for fuel and exhaust emissions, the eco-friendly car market is forecast to show high growth rates. There is much demand for high efficiency, miniaturized and low cost battery packs, which are critical to the growth of the eco-friendly vehicle market. Battery pack manufacturers are required to develop optimized internal Electronic goods within the battery pack.

We are providing optimized layout design/products according to client/specifications utilizing modules, wire harnesses and flexible Busbar to make full use of the limited space in the battery pack.

Types and purposes

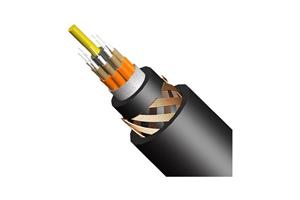

• Flexible busbar

Provide the best layout for the limited space available in battery packs.

• MSD

- We have developed integrated modules with main parts including the MSD/Current Sensor.

- We developed the connection process to connect the general cable layout and HV connector (Sleeve Welding)

- We designed an Inter Busbar that is located between modules, and the input/output cable harness.

Benefits

• Miniaturizes the battery pack, adapting the flexible Busbar layout

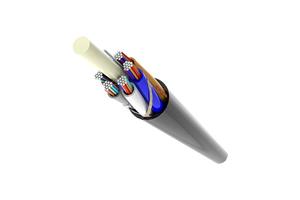

• Insulation and usability through non-shrinkage halogen-free tubes

• Wiring reliability within the battery pack using brackets, protectors, etc.

• Use of detachable Busbars for connectivity and also pack assembly to obtain the benefits of harnesses using flexible cables for input/output terminals