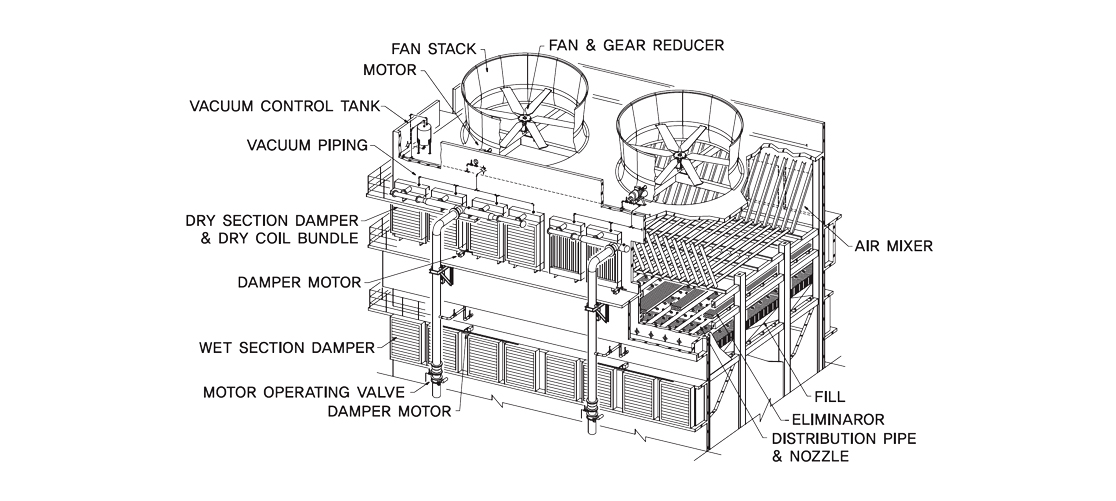

WET & DRY TYPE TOWER Structure chart

Features of KCL-WD TOWER

1. High-efficiency performance

Among the large-capacity cooling tower systems, KCL-WD Tower guarantees superior performance compared to the orthogonal flow-type cooling towers.

High efficiency cooling tower system is guaranteed especially through the PVC fill, which is built precisely for the industrial purpose.

2. Idealistic water distribution system

The use of nozzles are designed to distribute water evenly without clogging. And its’ cone shaped water distribution ensures excellent cooling performance in any environment.

3. Less space

Unlike an orthogonal typed cooling tower system, it is possible to install a large capacity cooling tower system in a narrow installation space.

4. Material selection

Concrete, FRP, steel, wood and other materials can be used in building the cooling tower systems.

5. Recirculation prevention

To minimize air recirculation, the distance between the air inlet and the discharge cylinder is maintained at a precisely calculated distance.

Plume abatement system agreement

1. Among the plume abatement technologies reflected in the domestic market, the plume abatement cooling tower system, which is proved and satisfy the performance with the American CTI ATC-150 CODE standard, is the KIMCO cooling tower only.

2. Design conditions of the plume abatement system

The standard design for the winter season is: DBT = 0 ℃ or more and RH = 80% or less

3. Within the design, condition for reducing plume reduces 90% of plume and 80% for reducing plume length based on the standard cooling towers.

Comparison of Plume

Plume Abatement Cooling Tower

Psychrometric Chart of Plume Abatement Cooling Tower

Plume Abatement