CKL-TOWER Strucyure chart

Features of CKL-TOWER

1. CONTAMINATION FREE

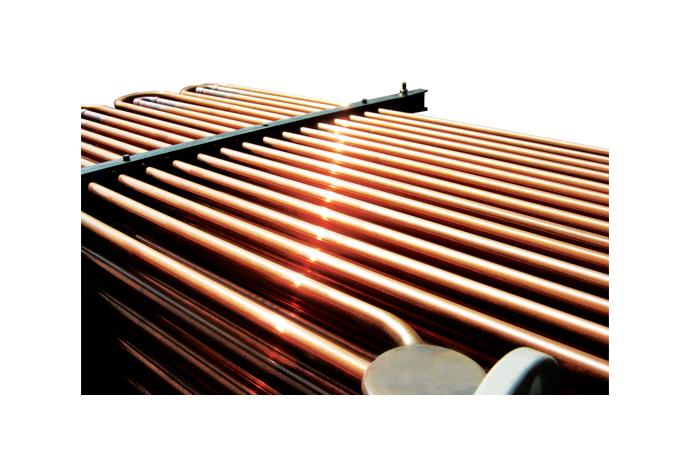

Unlike an open cooling tower, which heat is exchanged by the direct contact with air, CKL model, a closed cooling tower, is a type in which cooling air is circulated in the coils of coils, or stainless steel and coils with air being brought into indirect contact with each other. Also, CKL model does not cause contamination of cooling water through the absence of direct contact with external air.

2. ANTI CORROSION

Coolant circulation coils of copper or stainless steel frees the cooling tower from oxidation or other corrosion.

3. Enabled plume abatement operation

Since the coils are installed on both sides of the fan, plume abatement operation is possible under the low plume abatement or low-load temperature driving, and when coil’s sprinkling water is not on one side.

4. Optimal design for airflow

The optimum arrange of Fan, filler, and coil eliminates the air flow’s dead area, and improves its’ efficiency.

5. All year round operation

CKL series is an enclosed cooling tower, is an enclosed cooling tower system for when is sensitive condition for contamination or needs continuous operation throughout the year such as: semiconductor equipment, computer rooms, emergency power plants, etc.

6. Performance Guarantee

All of CKL’s enclosed models are the cooling tower systems that are certified by STD-201 of CTI