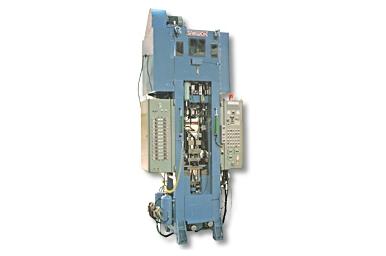

삼원종합기계 5en d.png)

Model NO.

SW - 100 - MC

Specifications

|

Features

•The crank type mechanism of the machine provides strong power with high accuracy and consistent pressing force.

•Main drive system served by centralized oil bath system ensures long life operation and few mechanical trouble.

•Using Ejection Position Constant system that ejection position is always the same regardless of filling height can make the operation and handling more easier

•Unique floating die pressing system and stopper design ensures accurate and uniform density balance.

•The use of the C-type tool holder(Die set)can produce parts of uniform density with five steps, upper 2 steps and lower 3 steps.

•All handles and gauges to control can be operated by motor and the digital counter on control panel.