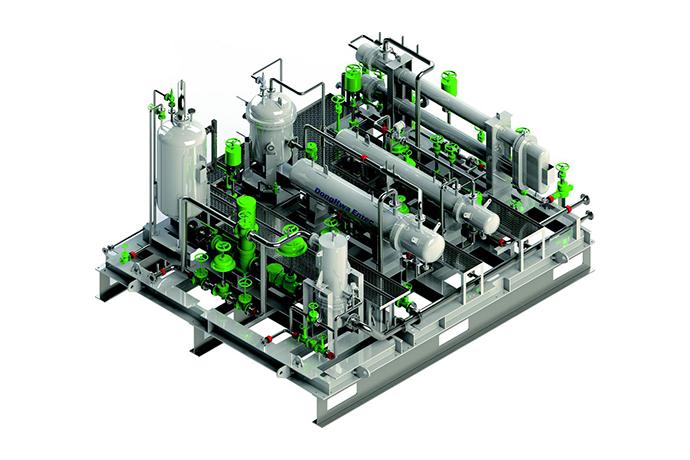

System configuration Fuel Gas Supply System(FGSS) is used to supply a fuel gas to ME-GI engine. The high pressure LNG is being supplied by HP liquefied natural gas pump and then, vaporized to natural gas. Glycol Water is generally used to heat-source for vaporizing liquefied natural gas, and Glycol Heating System is accompanied including Glycol Tank and Glycol Pump.

Fuel Gas Supply System(FGSS) is used to supply a fuel gas to ME-GI engine. The high pressure LNG is being supplied by HP liquefied natural gas pump and then, vaporized to natural gas. Glycol Water is generally used to heat-source for vaporizing liquefied natural gas, and Glycol Heating System is accompanied including Glycol Tank and Glycol Pump.

Main fuel supply system package unit for both high pressure 2 stroke engine and low pressure 4 stroke generator engines

IHM(intermediate Heat Medium) Heater package unit

IHM Tank

Container of IHM(50% Glycol + 50% water)

IHM Pump

Circulate the IHM from the LNG vaporizer to the IHM heater

IHM Heater

Heating IHM using steam with automatic temperature control

Vaporizer package unit

For 2 stroke high pressure main dual fuel engine

• High pressure vaporizer

Vaporization of high pressure super-critical LNG to the main engine

For 4 stroke low pressure generator engines

• Forcing vaporizer

Controlled vaporization to keep high methane number

• Mist separator

Seperation of heavy hydro carbonsand flows only high methane gas to the engines

• Fuel gas heater

Fuel gas heating to meet the requirements of the generator engines

Type of Vaporizer

A. Hairpin type High Pressure Vaporizer

Already field proven shell & tube type can be opened for mainternance biggest installation area needed

B. Spiral Flow type Pressure Vaporizer

Compact installation area needed already field proven heat exchanger

C. PFHE Plate–Fin Heat Exchanger

Core part is built by stacking layers of corrugated fins, parting sheets and side bar. And then it is brazed under high temperature condition.

D. PCHE Printed Circuit Heat Exchanger (Diffusion bonded Compact Heat Exchanger)

Diffusion bonding under high pressure and temperature after etching of channel form on the plate

Application

LNG Fuelled Small/Mid-Scaled

The FGSS have been in service on almost any type of marine application on container vessels, tankers of all sizes, bulk carriers, car carriers, RoRo and general cargo vessels