Ejector Condenser is a combination of Ejector which constantly ejects air to maintain a state of vacuum inside of Vacuum Steam Condenser, by using steam, and condenser which condensing and re-circulates the used steam.

If air infiltrates into Vacuum Steam Condenser for Steam Turbine, it wraps surface of tube and subsequently, the heat-transfer efficiency drops and vacuum state of Surface Condenser is released. Consequently, the efficiency of turbine falls down.

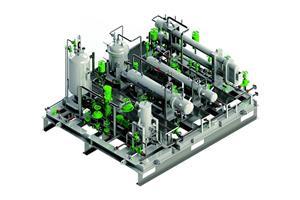

Therefore, Steam Ejector is used to eject air from Condenser, and Surface condenser is used to collect discharging steam accompanied with air, by using cooling water. For the reuse and efficiency, this condensate is mainly turned back to Surface Condenser through steam strap. Generally, Ejector Vacuum System is comprised of first stage Ejector and middle Surface Condenser, and second stage Ejector and final Surface Condenser. Since any rotating instrument is not included, it has advantage such as easy maintenance.

Necessity of Ejector system

The vacuum degree is decreased if the air is penetrated to vacuum surface condenser for turbine and result the decrease of power of turbine. Therefore steam driving ejector is necessary in order to remove air in vacuum surface condenser and ejector condenser is necessary in order to condense the driving steam. Usually ejector vacuum system is consisted of 1st ejector, inter condenser, 2nd ejector and after condenser. Comparing to vacuum pump, maintenance is not

needed because there is not rotation machinery using electricity.

Ejector Vacuum System