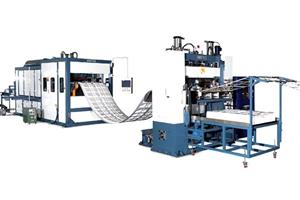

XPS Foam Board Extrusion Line [TYPICAL SPECIFICATION]

|

MODEL |

XPS100-130 |

XPS120-150 |

XPS150-200 |

XPS180-235 |

|

|

Thickness (mm) |

20-60 |

20-80 |

30-180 |

50-200 |

|

|

Width (mm) |

600-900 |

600-900 |

600-900 |

600-900 |

|

|

Length (mm) |

1,00-3,00 |

1,00-3,000 |

1,00-3,000 |

1,00-3,000 |

|

|

Throughput |

Conventional |

250-300 |

450-500 |

650-700 |

1,000-1,200 |

|

FOMICO®* |

350-400 |

550-700 |

800-900 |

1,500-2,000 |

|

|

Density (kg/m3) |

28-40 |

28-40 |

28-40 |

28-40 |

|

|

Extruder type |

Tandem |

Tandem |

Tandem |

Tandem |

|

|

Screw dia. (mm) |

100 and 130 |

120 and 150 |

150 and 200 |

180 and 235 |

|

|

L/D |

32/1 and 32/1 |

32/1 and 31/1 |

33/1 and 32/1 |

31.5/1 and 33/1 |

|

|

Blowing agent |

CO2, DME, HFC, HFO, |

CO2, DME, HFC, HFO, |

CO2, DME, HFC, HFO, |

CO2, DME, HFC, HFO, |

|

|

Barrel material |

[1st & 2nd, SACM] (Bimetallic) |

||||

|

Drive system |

A.C Motor & Variable Frequency Inverter |

||||

|

Gear Box** |

SNCM21 heat treatment and polishing |

||||

|

Thermal conductivity (10℃) |

0.025~0.026 W/MK |

||||

|

Compression strength |

180 ~ 300 kPa |

||||

|

Available edge finish |

Square edge |

|

|||

|

Ship lap |

|

||||

|

Tongue and Groove |

|

||||

Notes:

FOMICO®* incorporates BARR‘s ET/VBET screw technology which provides customers with higher throughput and lower energy consumption than conventional screw designs.

-The Gear Box** has been designed and its performance validated using the „Super-Computer“ available at the Korean Institute of Science.

-The gear box incorporates bearings providing a 10 year service life.

-The line design can be customized to meet specific customer requirements. For example, a Zambello & Flender gearbox is available as an option.

Product overview

Myung-il Foamtec Co. enjoys steady growth since it was established in 1975. The company started to manufacture and export

XPS thermal insulation board machine in 2002 and marketed XPS thermal insulation board products to the domestic market in 2003.

Today, the company exports its products to more than 40 countries around the world and engages in sustainable marketing activities

to grow into a global brand.

Major strengths

FOMICO products applied with BARR’s innovative screw design deliver higher level of product quality and productivity.

The rich know-how by STARFOAM Business Division not only ensures reliable quality but also unique design and convenience to let all

consumers experience highest level of satisfaction.