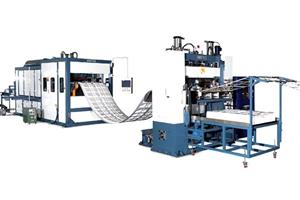

PS FOAM SHEET EXTRUSION LINE (TYPICAL SPECIFICATION)

|

MODEL |

PS80-105 |

PS90-120 |

PS100-130 |

PS115-150 |

PS150-200 |

|

|

Thickness (mm) |

1.0 ~ 3.5 |

1.0~4.0 |

1.0~4.5 |

1.0~6.0 |

1.0~6.0 |

|

|

Width (mm) |

500~1,200 |

500~1,200 |

500~1,200 |

500~1,200 |

500~1,200 |

|

|

Throughput |

Conventional |

130 |

200 |

270 |

350 |

550 |

|

FOMICO®* |

150~200 |

230~280 |

320~400 |

450~550 |

650~700 |

|

|

Density (kg/m3) |

40~130 |

|||||

|

Extruder type |

Tandem |

Tandem |

Tandem |

Tandem |

Tandem |

|

|

Screw dia.(mm) |

80 and 105 |

90 and 120 |

100 and 130 |

115 and 150 |

150 and 200 |

|

|

L/D |

34/1 and 32/1 |

32/1 and 32/1 |

33/1 and 33/1 |

32/1 and 31/1 |

33/1 and 32/1 |

|

|

Blowing agent |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

|

|

Drive system |

A.C Motor & Variable Frequency Invertor |

|||||

|

Heating |

Electric Heaters |

|||||

|

Machine weight (kg) |

15,000 |

17,000 |

19,000 |

23,000 |

32,500 |

|

|

Barrel material** (OPTIONS) |

[1st & 2nd, SACM645] (Bimetallic) |

|||||

|

Control system (OPTIONS) |

Touch Screen controlled with PLC |

|||||

|

Winder (OPTIONS) |

Tension control |

|||||

|

Pumping system (OPTIONS) |

Nikkiso&Lewa duplex or triple diaphram pump |

|||||

Notes:

- FOMICO®* incorporates BARR‘s ET/VBET screw technology which provides customers with higher throughput and lower energy consumption than conventional screw designs.

- The blowing agent** is added via a diaphragm pump.

- An optional metering system is also available.

- The line design can be further customized to meet specific customer requirements.

Product overview

Myung-il Foamtec Co. built its product know-how for over 30 years since it developed and started to supply PS foam sheet machines in 1984.

The constant efforts to drive technological innovation, improve quality, and develop a wide variety of new products help Myung-il Foamtec’s growth into a global company.

Major strengths

PS foam sheet extrusion line by Myung-il Foamtec Co. enjoys a stable quality system backed by constant product R&D that also saves maintenance cost.