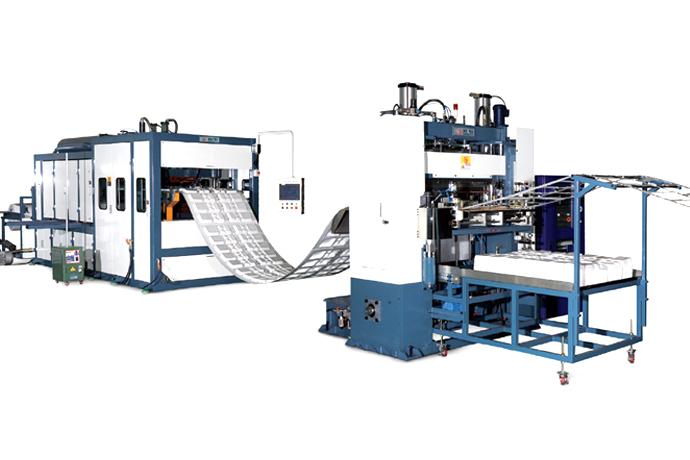

AUTO VACUUM FORMING MACHINE

|

MODEL |

MI-2C-1,100 x 1,200 |

MI-2C-1,100FT |

MI-2C-1,000FT |

|

Forming size (Max) |

W 1,100mm x L 1,200mm |

W 1,100mm x L 1,200mm |

W 1,000mm x L 1,000mm |

|

Forming size (Min) |

W 600mm x L 600mm |

W 600mm x L 600mm |

W 500mm x L 500mm |

|

Forming depth* |

Max. 120mm |

Max. 120mm |

Max. 120mm |

|

Material transfer |

PSP, PP, PS, PE, PVC, PET, ABS, HIPS, etc |

||

|

Material thickness |

1 mm ~ 4 mm For Foam Sheet |

1 mm ~ 4 mm For Foam Sheet |

0.2 mm ~ 1.5 mm For Roll Sheet |

|

Forming capacity |

4.0 sec/ 15 cycle/ min |

4.0 sec/ 15 cycle/ min |

4.0 sec/ 15 cycle/ min |

|

Table driving |

Hydraulic Power |

Hydraulic Power |

Hydraulic Power |

|

Material transfer |

A.C Servo Motor 5 HP |

A.C Servo Motor 7.5 HP |

A.C Servo Motor 5 HP |

|

Electric control |

PLC & Sequence Program |

PLC & Sequence Program |

PLC & Sequence Program |

|

Temperature control |

PID Digtal Control & Touch Panel |

PID Digtal Control & Touch Panel |

PID Digtal Control & Touch Panel |

|

Cutting system |

Auto Trimming Machine |

In Line Hydraulic Press |

Auto Trimming Machine |

|

Power consumption |

140Kw |

160Kw |

150Kw |

|

Machine size |

W 1,850mm x L 6,000mm x H 2,500 |

W 1,850mm x L 11,000mm x H 2,500 |

W 1,850mm x L 6,000mm x H 2,500 |

|

Machine weight (kg) |

Approx. 8,000kg |

Approx. 20,000kg |

Approx. 8,000kg |

Notes:

- Forming depth and other equipment features are designed to meet customers‘ specific requirements

AUTO TRIMMING PRESS MACHINE

|

MODEL |

MI-2C-1,100 x 1,200 |

MI-2C-1,000FT |

|

Cutting size (mm) |

W 1,100mm x L 400mm |

W 1,100mm x L 300mm |

|

Cutting depth* |

Max. 120mm |

Max. 120mm |

|

Material |

PSP, PP, PS, PE, PVC, PET, ABS, HIPS, etc |

|

|

Material thickness (mm) |

1 mm ~ 4 mm For PS Foam Sheet |

0.2 mm ~ 0.5 mm |

|

Trimming speed (cycle/min) |

100 |

100 |

|

Table-vertical movement(mm) |

Max. 160 |

Max. 160 |

|

Machine drive motor |

15 HP (Vector Invertor) |

15 HP (Vector Invertor) |

|

Electric control |

Touch Panel, PLC & Sequence Program |

Touch Panel, PLC & Sequence Program |

|

Power consumption |

14Kw |

14Kw |

|

Machine size (mm) |

W 2,300 x L 3,500 x H 2,700 |

|

|

Machine weight (kg) |

Approx. 7,000kg |

Approx. 7,000kg |

Notes:

- Cutting depth and other equipment features are designed to meet customers‘ specific requirements

Product overview

Myung-il Foamtec’s former business has grown alongside extrusion line business. Latest R&D direction aims at making formers compact and multi-functional.

Major strengths

Myung-il Foamtec’s formers deliver optimal performance for a wide variety of materials and higher production to arm the company with global competitive edge.