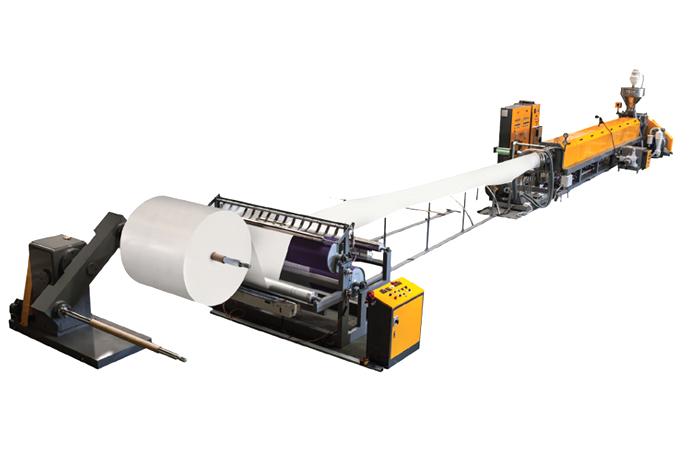

PE FOAM SHEET EXTRUSION LINE (TYPICAL SPECIFICATION)

|

MODEL |

PE 90 |

PE 105 |

PE 120 |

PE 130 |

PE 150 |

PE 170 |

PE 180 |

PE 200 |

PE 210 |

|

|

Thickness (mm) |

0.5~4.0 |

0.5~6.0 |

0.5~8.0 |

1.0~10.0 |

1.0~15.0 |

2.0~18.0 |

2.0~18.0 |

1.0 ~ 20 more |

1.0 ~20 more |

|

|

Width (mm) |

1,300 |

1,500 |

1,600 |

1,700 |

1,800 |

2,000 |

2,000 |

2,000 |

2,100 |

|

|

Throughput |

Conventional |

110 |

150 |

200 |

260 |

350 |

430 |

450 |

500 |

580 |

|

FOMICO®* |

130~150 |

180~220 |

250~300 |

300~350 |

400~455 |

500~550 |

550~600 |

600~650 |

650~750 |

|

|

Density (kg/m3) |

15 ~ 120 |

|||||||||

|

Screw dia. (mm) |

90 |

105 |

120 |

130 |

150 |

170 |

180 |

200 |

210 |

|

|

Blowing agent |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

Hydrocarbon |

|

|

Drive system |

A.C Motor & Variavle Frequency Invertor |

|||||||||

|

Heating |

Electric Heaters |

|||||||||

|

Machine weight(Approx) |

13,500kg |

15,000kg |

17,000kg |

18,000kg |

21,000kg |

23,000kg |

24,000kg |

25,000kg |

27,000kg |

|

|

Barrel material (OPTIONS) |

[1st & 2nd SACM645] (Bimetallic) |

|||||||||

|

Extruder type (OPTIONS) |

Tandem |

|||||||||

|

Control system (OPTIONS) |

Touch Screen controlled with PLC |

|||||||||

|

Pumping system (OPTIONS) |

Nikkiso&Lewa duplex or triple diaphram pump |

|||||||||

Notes:

- FOMICO®* incorporates BARR‘s ET/VBET screw technology which provides customers with higher throughput and lower energy consumption than conventional screw designs.

- The blowing agent** is added via a diaphragm pump.

- An optional metering system is also available.

- The line design can be further customized to meet specific customer requirements, for example, with the inclusion of a tandem extruder.

Product overview

Myung-il Foamtec Co. steadily built its know-how ever since it developed and supplied PE foam sheet machines in 1984.

It started exports of PE foam sheet extrusion lines from 1986, which since then positioned as the major product at Myung-il Foamtec.

Major strengths

PE foam sheet extrusion lines by Myung-il Foamtec Co. ensures a stable extrusion and proven energy-saving benefits.

The latest technological advances have contributed to developing an extrusion system that can manufacture a wide variety of products of consumers’ choice