Energy Saving Advanced RTO System, Regenerative Thermal Oxidation System

On 2002, we successfully performed R&D of Advanced RTO System with the support of Korea MOE. On 2004, its advanced technology was appointed as the New Environmental Technology ET Mark by Minister of Korea Ministry of Environment. On March 2006, we and our partner, SWC Japan Co., Ltd. successfully supplied & installed Advanced RTO System with VOC Concentrator for Gravure Printing Dry Line of TOKKA Co., Ltd. in Saitama, Japan

Futures and Benefits

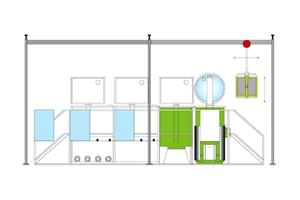

For more cost effective system to remove the exhaust VOC (volatile organic compounds)/Odor from industrial factories, we developed the unique horizontally rotating & distributing RTO with the square structure, instead of the conventional vertically rotating & distributing RTO with the cylinder structure: The vertical distributing rotor was advanced by the horizontal distributing rotor. The vertical distribution chamber with the cylinder structure was advanced by the horizontal distribution chamber with the square structure. The cylinder type regenerative thermal chamber was advanced by the square type regenerative thermal chamber. The rotor’s location, a core component, the built-in internal type vertically at the bottom center area of the system was advanced by the built-out external type horizontally at the lower area of the system. We developed also the unique rotor and the metal seal, providing the excellent durability and the effective sealing performance. We have 2 patents with the applied series 3 patents to Korea, Japan, China and USA.

ㆍHigh reliable over 95%+ VOC/Odor destruction removal efficiency with over 95%+ thermal energy recovery

ㆍAvailable a space-free installation by the excellent flexibility of the system design in dimension, width, height and direction

ㆍEconomic saving by 30%+ downsized system, space and low running cost

ㆍEnsure the reliability and the low maintenance cost by the semi-permanent durability of the major components

ㆍEasy maintenance of the rotor with the metal seal, key core components by the built-out external type horizontally at the lower area of the system

Application Fields

ㆍPainting Industry

ㆍCoating Industry

ㆍPrinting Industry

ㆍSemiconductor Industry

ㆍChemical & Pharmaceutical Industry

ㆍPaper & Textile Industry

ㆍFood Industry

ㆍWaste treating Industry etc

Process & Configuration of Advanced RTO System