For Automotive Plant & Machine Components/Parts Industries

Environmentally Friendly Casting Impregnation System

Since 1993 successful supply of Casting Impregnation System for Automotive Converter Housing, Sang Won has developed and improved the design & manufacturing technology for the optimum Casting Impregnation System with the repeating orders from Korean automotive customers.

These accumulated experiences have resulted in Sang Won being recognized as the Korea representative leader of environmentally friendly Casting Impregnation System.

Types

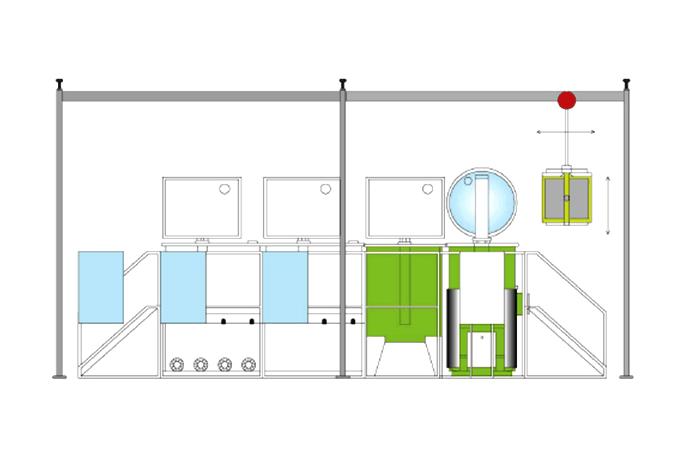

Top load in-line Impregnation Machine, fully Automatic with recycling sealant system

Top load batch type Impregnation Machine, semi-auto with recycling sealant system

Futures and Benefits

World wide best productivity by the fast cycle times+ Provide top quality impregnated products.

Available fully Automatic in-line Impregnation System, including also in-line to the previous machine/process and the next machine/process

Greatly reduce sealant consumption, water consumption and environmental trade effluent by RSS (recycling sealant system)

Accumulated experiences of design+ manufacturing+ site O&M provide the optimum Impregnation System to customer’s various requirements

Optional Water Recycling System continuously recovers and recycles the hot cure process water to maintain the process water cleanliness and process quality. The environmentally friendly system reduces waste water effluent and disposal costs

Application Fields

Automotive Casting Products

Aerospace & Defense Casting Products

Other Industry Casting Products, Components and Parts

Process & Flow of Recycling Sealant System