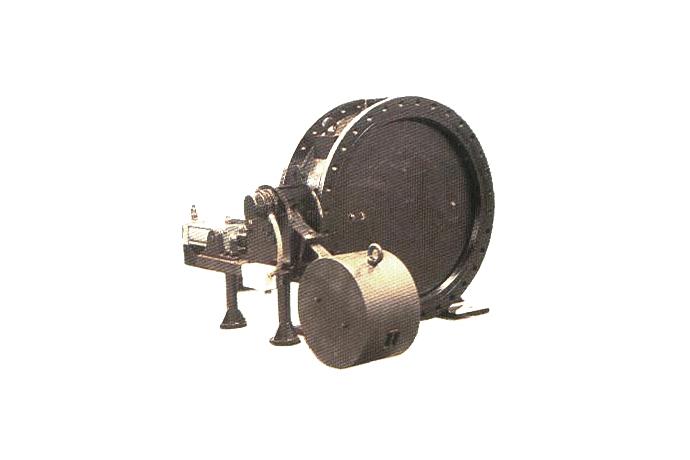

Non-Return Valve

Application

- Water works - Air conditioning

- Power plant - Gas plant

- Sewage plant - Chemical industry etc

- Heating and ventilation - Shipbuilding industry

- Desalination plant - Irrugation

Face to Face Dimensions

Conform to BS5155, ISO 5752, AWWA C504, KS B 2333

Production Range

- Size : DN 80 to DN2400 (3 inch to 96 inch)

- Working Pressure : Up to 30 bar

- Working Temperature : -20°C ~ + 160°C

Connection Flange

- BS4504 PN10, PN16 /DIN2501, PN10, PN16 ANSI B 16.1 CL. 125LB & B16.5 CL 150LB

- MSS SP 44 CL 150LB

- AWWA C207 Class D & E

- ISO 2531 PN10 PN16 / KS/JIS 10K, 16K, and 20K

Material

- Body : Cast Steel, Ductile Cast Iron, Stainless Steel, Aluminium Bronze

- Disk : Cast Steel, Ductile Cast Iron, Stainless Steel, Aluminium Bronze

- Stem : Stainless Steel, Monel, Inconel

- Seat : Rubber(EPDM, NBR, NR, FPM) Graphite, Stainless Steel

- Acc'y : Dash pot (Cushion Cylinder) Weight.

Combined Non-Return Valve

Definition

Emergency valve can control the flow direction in order to prevent the breakage of pipes by the reverse flow due to the sudden rising of the flow speed. When ordered by contral device. The closing speed of the valve disc can be adjusted.

Operation

- Opening valve

- Closing valve

- Keeping the valve open at the intermediate position

- Emergency self-closing

(adjustable disc closing time by two steps-site adjustment available)

Features

- Emergency valve can be substituted for butterfly valve & check valve.

- Control the flow by keeping the valve open at the intermediate degree.

- Adjustable the disc closing speed by two steps. When the valve close by position to prevent

(can be closed slowly at the 85 degree closing position to prevent water hammering)

Can be closed quickly be emergency situation to prevent the reverse flow as general check valve usage.

- The cost of the installation and maintenance can be reduced.

- Free from shaking and noise.