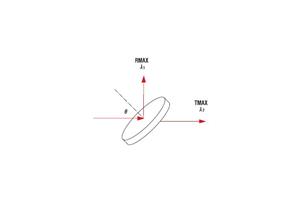

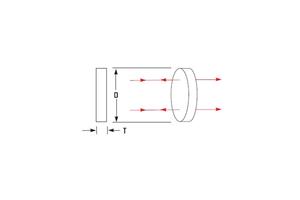

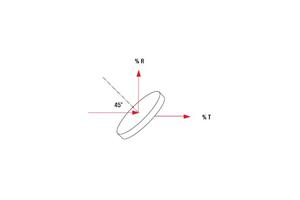

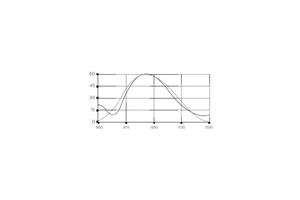

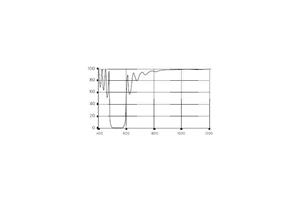

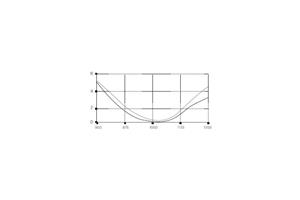

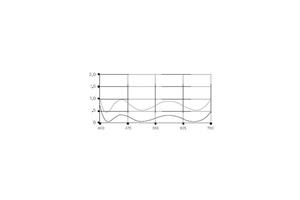

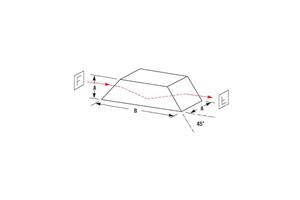

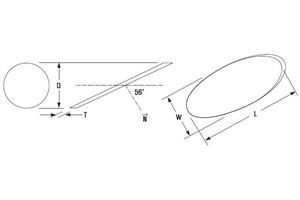

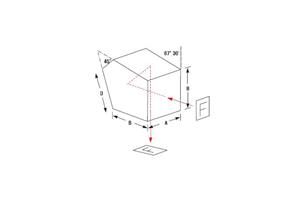

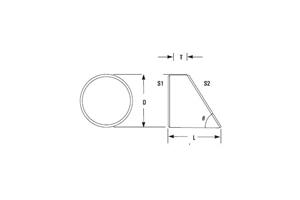

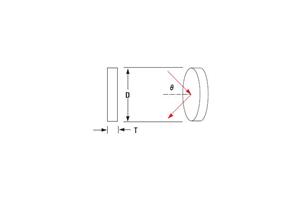

Mirrors are used in a wide range of beam steering, focusing and collimating applications. RMAX mirrors utilize multi-layer, dielectric thin films. Laser-Line RMAX Mirrors are designed for high reflectance at a single laser wavelength. High power coating designs are standard for select wavelengths. Broadband RMAX Mirrors provide high reflectance over a broad spectral range. They are also useful in narrowband applications in which it is necessary to vary the angle of incidence. Metal Mirrors are intended for applications involving lower power lasers, or broadband sources. They are less sensitive to wavelength, polarization and angle of incidence than dielectric mirrors. Solid Metal Mirrors are well suited for use in high power infrared laser applications. Copper must be coated with protected gold or silver, because it oxidizes very repidly. Molybdenum is generally used uncoated. It is a very hard material that does not oxidize, and has high reflectance above 3 μm. Substrates are available with plano/plano, plano/concave and plano/convex surfaces. Refer to the THIN FILM COATING section for coating information and specifications.

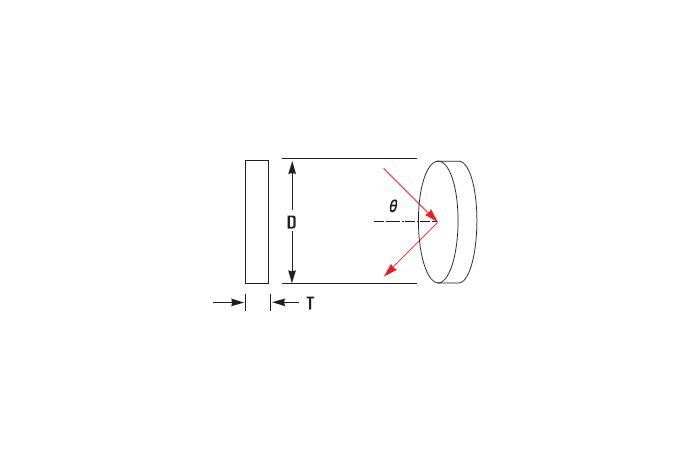

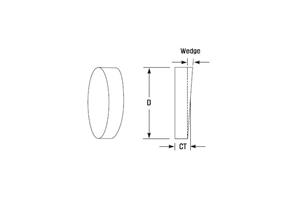

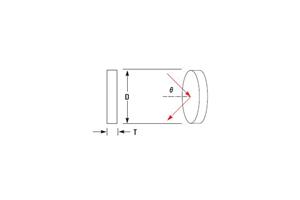

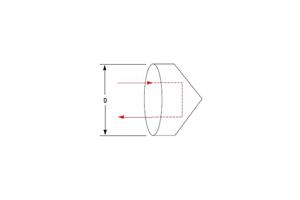

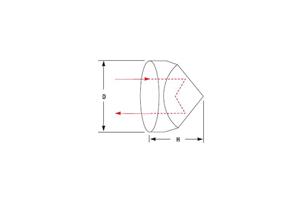

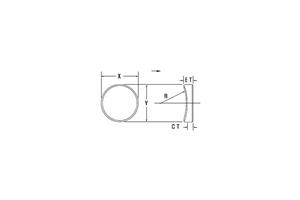

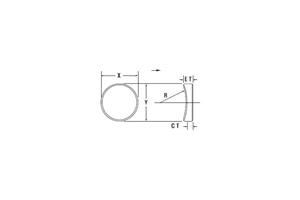

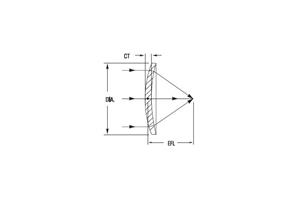

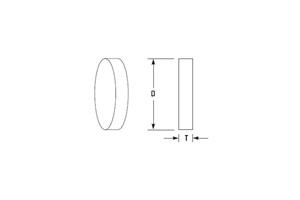

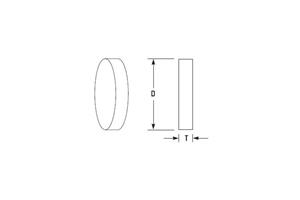

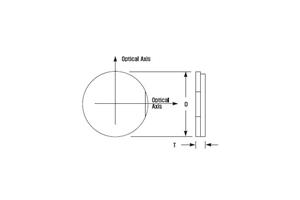

[Note : Thicknesses listed are exact for plano/plano substrates. For plano/concave and plano/convex substrates, center thickness (CT) depends on the radius of curvature.]