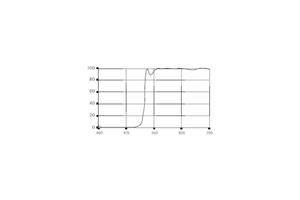

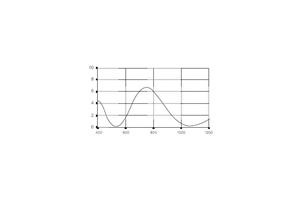

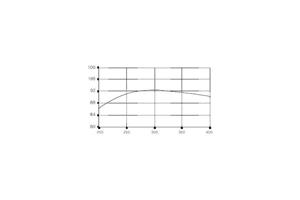

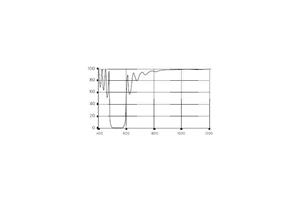

Bare GOLD has high reflectance in the near, mid and far IR regions. Gold does not oxidize, so it is not necessary that it have a protective dielecric overcoat. Bare gold, however, is very soft and easily scratched, and can only be cleaned by flow-washing with solvents, or by blowing the surface clean with a low pressure stream of dry air. Durability is greatly enhanced with a protective overcoat. Protected gold offers excellent reflectance from 700 nm through far IR and can be cleaned regularly using standard organic solvents. It is somewhat less sensitive to wavelength, angle of incidence, or polarization, so it is useful for a wide range of monochromatic and polychromatic. Gold is chemically Insert, thus it is well suited for harsh environments, such as DF and HF laser cavities.

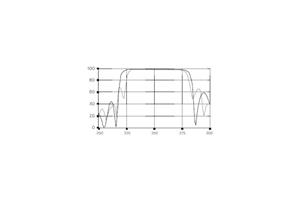

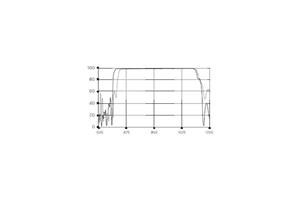

ENHANCED GOLD (EAG)

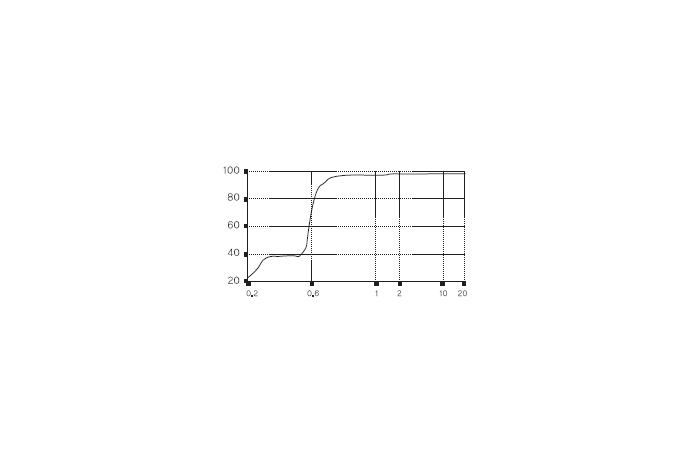

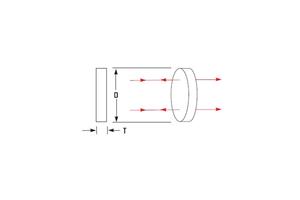

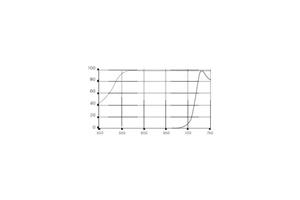

Enhanced Gold is comprised of gold overcoated with a multilayer dielectric film that is designed

to optimize reflectance at a specific wavelength. This coating is recommended for applications

involving high power CW lasers, especially when deposited on copper substrates, due to heat

dissipation characteristics of copper. The enhancing layer also greatly improves durability,

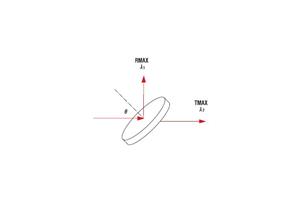

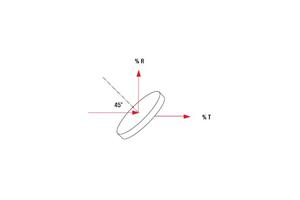

meeting MIL SPEC requirements. This coating is sensitie to wavelength, angle of incidence and

polarization. Reflectance values can be further optimized further by adding more layers to the

enhancing overcoat. This option is available upon request.

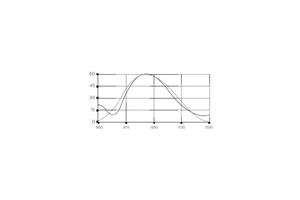

Commonly used in the visible and near infrared regions, enhanced gold increases reflectivity

at 800nm from about 98% to 99.5%

These and other coatings are available from stock on a variety of substrates. Please contact us for assistance with

fulfilling your requirements.