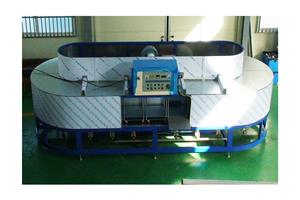

TECHNICAL DESCRIPTION

ㆍPRODUCTION CAPACITY : 15/ 30/ 50 pcs/ min

ㆍAVAILABLE HOUSING HEIGHT : 65~310mm

ㆍAVAILABLE HOUSING DIA :  60~

60~ 135

135

ㆍFIVE TANK TYPE

A) PRE-DEGREASING(WATER) : 35 5

5 (1~2 min)

(1~2 min)

B) DEGREASING : 55 5

5 (2~3 min)

(2~3 min)

C) RINSING(WASHING) : 35 5

5 (1~2 min)

(1~2 min)

D) PHOSPHATE : 50 5

5 (2~3 min)

(2~3 min)

E) RINSING(WASHING) : 50 5

5 (1~2 min)

(1~2 min)

F) DRY(140~160 x 5min)

x 5min)

ㆍCONVEYOR TURNING SPEED(ON PAINT SPRAY PROCESS : 3m~ 5m/min

ㆍINFRARED RAYS HEATING SYSTEM & AUTOMATIC TEMP. CONTROL TYPE

ㆍINDIVIDUAL OPERATION CONTROL PANNEL

ㆍ3 WAY TURNEL & 5 WTATER TANK TYPE

ㆍPAINT THICKNESS : 10~13

ㆍAUTOMATIC CONVEYOR SPEED CONTROLLER INSTALLED

ㆍOVER TEMP. PROTECTOR CONTROL/ SAFTY DEVICE INSTALLED

ㆍEMERGENCY STOP SYSTEM INSTALLED

ㆍREFLECTOR : WATER DISPOSAL SYSTEM INSTALLED

ㆍPAINT VISCOSITY(MIXED THINNER) : FORD CUP NO 4. 10~13 sec

ㆍTHINNER TYPE : ELECTROSTATIC THINNER

ㆍPAINT TYPE : ELECTROSTATIC PAINT

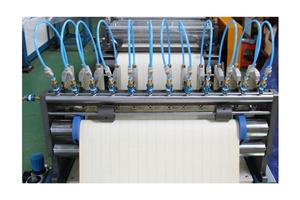

ㆍSPARY GUN TYPE : ELECTROSTATIC GUN

ㆍSTAINLESS STEEL TOP PLATE CONVEYOR & STAINLESS WIRE NET CONVEYOR OR HANGER TYPE CONVEYOR INSTALLED

ㆍREQUIRED PAINT LINE EQUIPMENT(REFER TO THE DETAILED LAYOUT)

: PRE TREATMENT(MESH CONVEYOR, 10.5m) x DRY OVEN(12.1m) x POWDER BOOTH(1.2m FOR 1 BOOTH)

x COOLING SYSTEM(2.1m) x BAKING OVEN(18m) x DUST COLLECTOR

x POWEDER COATING M/C x SPINDLE CONVEYOR(164m)

OPTIONAL PART

ㆍELECTROSTATIC THINNER

ㆍELECTROSTATIC PAINT

ㆍELECTROSTATIC PAINT GUN

ㆍELECTRICSTAIC CONTROL SYSTEM

ㆍCHAIN

ㆍSPARY TIP

ㆍPAINT FILTER

REMARK

ㆍTHE ABOVE PHOTO IS BASE ON SPINDLE TYPE.