TECHNICAL DESCRIPTION

ㆍPRODUCT CAPACITY : 10~25 pcs/ min

ㆍOUT PUT : 0.8~3.2 kg/ min

ㆍPUMP MOTOR : 0.75 kw

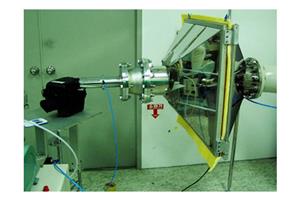

ㆍMIXING HEAD : 3200 RPM

ㆍMETERING PUMP UNIT : CHEMICAL GEAR PUMP

ㆍTANK : TROUBLE LAYER TANK SYSTEM

ㆍRESIN TEMP : 18~250

ㆍELECTRIC POWER : 380/ 220V x 3P x 50/ 60Hz

ㆍMACHINE SIZE : W1300 x L2000 x H1500

ㆍMACHINE WEIGHT : 2,500 kg

ㆍTANK VOLUME : 80 LITE(FOR POLY & ISO) & 60 LITE(FOR MC)

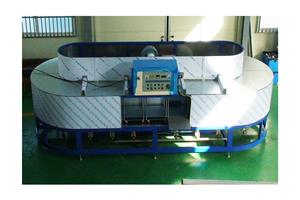

APPLICATION

ㆍTHIS MACHINE IS DESIGNED TO MANUFACTURE AN AUTOMOTIVE AIR FILTER OF POLYURETHANE TYPE.

ㆍROUND/ SQUARE/ ANY SHAPE CAN BE MADE BY PLC SYSTEM.

FEATURE

ㆍTOUCH PANNEL CONTROL SYSTEM

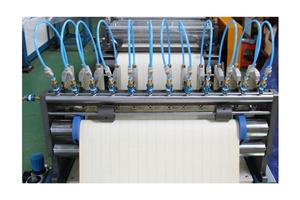

ㆍAUTOMATIC WASHING SYSTEM IS INSTALLED ON THE NOZZLE

ㆍX-Y ROBOT MOVING SYSTEM(WITH PLC PROGRAM) INSTALLED

ㆍ2 POLY TANK(FOR YELLOW & BLACK COLOR) & 1 ISO TANK & 1 MC TANK INSTALLED

OPTIONAL PAPRT

ㆍPU RAW MATERIAL(POLY & ISO)

ㆍMATERIAL MIXING & LOADING PUMP

ㆍNOZZLE & IMPELLER

ㆍPOLY & ISO CHEMICAL PUMP

ㆍPP MOLD OR MASTER MOLD

ㆍRUBBER HOSE

ㆍ3 RT CHILLER(FOR COOLING & HEATING SYSTEM)

ㆍASSEMBLE TRANSFER CONVEYOR