1. Overview

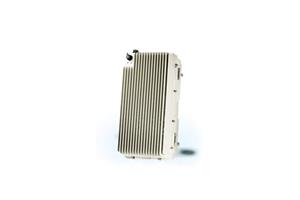

• A production equipment that completing the battery through activating the battery and expression of voltage and capability after cell assembly followed by chemical process Cell

2. Characteristics and its commercial use

• Charge/discharge using Constant Voltage(CV) and Constant Current(CC) system

• Flexible schedule and management dependent on production progress

• Real time log and storage of cell performance data

• Highly accurate charge/discharge device with narrow current and voltage management range, less than 0.1%

• F/W Update through GUI is available

• Automatic fire extinguishing action as it is connected to fire extinguishing system

3. Specification

| No. | Item | Content | Note | |

| 1 | Equipment Size(W*D*H) | Rack | ||

| Main Unit | 1459.4 * 376.6 * 950mm(W*H*D) | |||

| 2 | Control/power method | S/W(PWM) Type - Current AC revival each CH control method | ||

| 48 CH/JIG | ||||

| 3 | No. of CH/JIG | |||

| 4 | Contorl/mechanism arrangement | Combined Top and bottom mechanism/control | ||

| 5 | Circuit safety | Circuit protecting overheating OVP, OCP, OTP Comply 6 major stability categories | ||

| 6 | Temperature for room maintenance | 25°C+2°C~25°C-2°C(Exhaust duct installation at each stage) | ||

| 7 | Contact method | Probe Pin (bottom up) | ||

| 8 | Fire fight safety practice | Charge/discharge room firewall, temperature/smoke/spark sensor Security center connection, automatic fire extinguishing appliances | ||