Ceramic Fiber Board is lightweight refractory and insulation materials which produced through wet forming process with organic and inorganic binder.

Features

• Low thermal conductivity

• Thermal shock resistance and Hot stability

• High tensile strength

• Sound absorption

• Easy cut and installment

• No asbestos

• Chemical corrosion resistance

• Low heat storage capacity

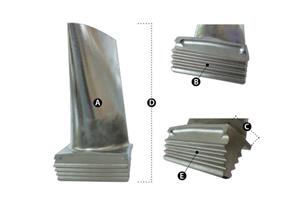

Product size (㎜)

• Length : 1200, 1000, 900

• Width : 1000, 600

• Thickness : 6, 10, 12.5, 25, 38, 50

Use of product

• Wall for different furnaces and electric furnaces

• Supplymentary insulation for fire resisting bricks

• Mechanical industry

Technical characteristics

| Type | 1260STD | 1260HP | 1400 | 1450 | |

|---|---|---|---|---|---|

| Continuous use temerature ℃(℉) | 1050(1922) | 1100(2012) | 1200(2192) | 1350(2462) | |

| Density(kg/㎥) | 220 450 | 220 450 | 220 450 | 220 450 | |

Pernament linear shrinkage(%) (24hrs@320kg/㎥) | 2-3 (1000℃) | 2-3 (1100℃) | 2-3 (1200℃) | 2-3 (1350℃) | |

Thermal conductivity (w/m.k), (128kg/㎥) | 0.12(600℃) 0.20(800℃) | 0.12(600℃) 0.20(800℃) | 0.12(600℃) 0.20(1000℃) | 0.12(600℃) 0.20(1000℃) | |

| Chemical component(%) | Al2O3 | 46 | 47~49 | 52~55 | 39-40 |

| Al2O3+SiO2 | 97 | 99 | 99 | - | |

| ZrO2 | - | - | - | 15-17 | |

| Fe2O3 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O + K2O | ≤0.5 | 0.2 | 0.2 | 0.2 | |