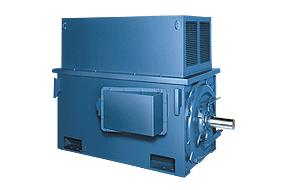

- Reduction of Loss by the use of High-End Electrical Steel Sheet, and Expansion of Torque Maintaining Area at High Speed (High Frequency Range)

- Improvement of Winding Insulation, Heat Transfer and Durability by the Stator Vacuum Impregnation

- Realization of Lightweight through the Design with Magnetic Field Analysis

- Use of High Reliability SPEED SENSOR

- Use of Electric Wire which is exclusive for Vehicle

- Noise and Wear Reduction by improving of Precision Degree of Coupling Connection.

- Maximization of Cooling Effect through the Use of Aluminum Frame to get High Power Density, and by the Cooling System Design

- Realization of Miniaturization and Lightweight through High Power Density(kW/kg)

▷ Maximization of Cooling Effect of the Heat generated by the High Current Density of Winding through the Use of Aluminum Frame and Water-Cooled Cooling System.

▷ Application of High-End Electrical Steel Sheet with Low Core-Loss and High Permissible Magnetic Flux.

- Securing of Structural Strength Stability in High Speed Area

- Spline Shaft Driving Method

- Reinforcement of Insulation Performance prepared for Inverter Surge Voltage