System Diagram (An apparatus collecting floating oil on the surface by using vacuum self-priming pump)

A device sucking impurities in the oil, which float on the surface freely. Floating oil skimmer is used together with a device for separation of oil from water in vacuum self-priming pump.(in case of suction, oil, water and air are all sucked together)

Removal of a large quantity of oil through a forced suction by pump.

Its intake is located on the surface, which makes it possible to utilize the detention time of storage tank and PIT to the maximum maximize and increase the efficiency of the separation of oil from water.

Suitable for the removal of oil floating on large water surface.

Complete removal of minute oil layers by forced suction on floating.

Prevention of big floating materials from being sucked by the strainer(blockade of the maximum size of 50 m/m)

SLUDGE will not be formed because it floats on the surface.

With a suction-speeding pipe installed in the intake a whirlpool hole is created as it sucks whirling water. And as surface oil is sucked first into the whirlpool hole, the amount of water intake is relatively small and regulation on the height of the surface is not required.(blockade of the maximum size of 50 m/m)

The Picture to feed the floating scum and bubble to the tank

Place for Use

Such place as storage tank or PIT where oil occurs a lot

the upper part of washing device of cutting fluids for removal of oil and bubble.

Big oil spill on stream or river

Place where the capacity of best oil skimmer is insufficient

Removable OIL

hydraulic fluid, lubricant, rolling oil, crude oil, bunker C-oil, coolant oil, cleansing oil, anti-corrosible oil, vegetable oil, bubble, floating materials, slurry, and etc.

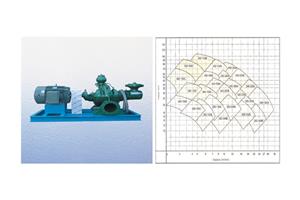

| The purposes and characteristics of the vacuum self-priming and scum recovery pump. |

|---|

| Place for Use | Comparison between the rival and similar products available in the domestic and global markets | Such place as storage tank or PIT where oil occurs a lot

the upper part of washing device of cutting fluids for removal of oil and bubble.

Big oil spill on stream or river

Place where the capacity of best oil skimmer is insufficient | All of the equipment used for the cleanup of oil spills in the high seas has to be imported at a steep price, which has caused crisis of contingency plans inhibiting and difficulty in conducting efficient maintenance. Our skimmer pump helps maximize production and maintenance efficiency by removing waste matter at factories which produce food, textiles and paper products, or at waste water and sewage treatment plants that have relied on labor-intensive processes for transport. Using conventional pumps for the transportation of scum has not been an easy job as the pump resorts tofluid speed and tends to fail when air gets into the system, requiring a vacuum mechanism to facilitate the transport capability by combining the vacuum and generic pumps with the vacuum tank. Our skimmer pumps require only the pump and skimmer, which makes it easy to operate and maintain. | | Product Function | ⊙ Vacuum Self-Priming Pump : It is dubbed 'Vacuum Self-Priming Pump' because, due to its unique liquid-ring design, it not only operates continuously just through air-suction once it is initially filled with water inside the pump, but also produces a strong self-absorbing power( 9.2. meters of self-absorbing height based on normal temperature pressure for cleaning) for a self-absorbing feed of fluids mixed with air, high viscous fluids, and fluids with low specific gravity

⊙ Skimmer pump : As a pump to recovery floating matters by using vacuum self-priming pump & skummer, It force to suct and feed floating matters |

|

| |

| Performance comparison of vacuum self-priming scum recovery pumps and the conventional submersible scum pumps |

|---|

| Category | Vacuum self-priming scum/recovery pump | Domestic submersible scum pump | International brands of submersible scum pump | Scum recovery pumps (Vacuum self priming pumps)

* PCT application (Utility design and invention patents) | The pump is installed on a float or above ground that sucks oil scum from the water surface by generating an instant vacuum. | It is difficult to maintain and put into commission due to the floating requirements, while water and oil that are funneled can be easily recovered. (More likely to affect the motor from the electric leakage) | It is difficult to maintain and put into commission due to the floating requirements, whilewater and oil that are funneled can be easily recovered. | | Suction power | Powerful suction based on the vacuum being generated (for scum recovery within a 1 meter range) | Recovery limited to the scum retained in the suction hopper | Recovery limited to the scum retained in the suction hopper | | Durability | Built with stainless steel and PVDF, which show high resistance to acidity and alkaline. | Recurring pump failures reported (built in cast molding) | Recurring pump failures reported (built in cast molding) | | Dangers involving electrical work | There is less likelihood of electric leakage as the rig is installed on dry ground in addition to the convenience of installation | There is a higher likelihood of electric leakage in addition to the difficulties of installation, which uses floats. | There is a higher likelihood of electric leakage in addition to the difficulties of installation, which uses floats. | | Transport volume | Various size available (25A~100A) with maximum 1.0㎥/min | Caliber: 40A fixed | Suction capacity: maximum 0.8㎥/min | | Weight (for super compact size) | 23kg | 80kg | 130kg | | Displacement capacity | Maximum 30m | Maximum 8m | Maximum 20m | | Application range | Its wide application capability includes not only scum but also the remaining recovery or transport | Its application is limited to scum recovery | Its application is limited to scum recovery | | Unique property | Powerful vacuum allows suction and the transport of scum and oil by force. | Whatever is sucked into the hopper is transported. | Whatever is sucked into the hopper is transported. |

|