The heat sink manufacturing processes include pressing, extrusion,

bonding, heat piping, brazing and the circulation of liquids (water, refrigerant, etc.).

The price and performance vary according to the material quality, weight and

the methods used.

Recently, many special products have been developed; however, the brazing method is recognized as the most advanced technology considering the radiation surface area, heat conductivity and air circulation.

| Name |

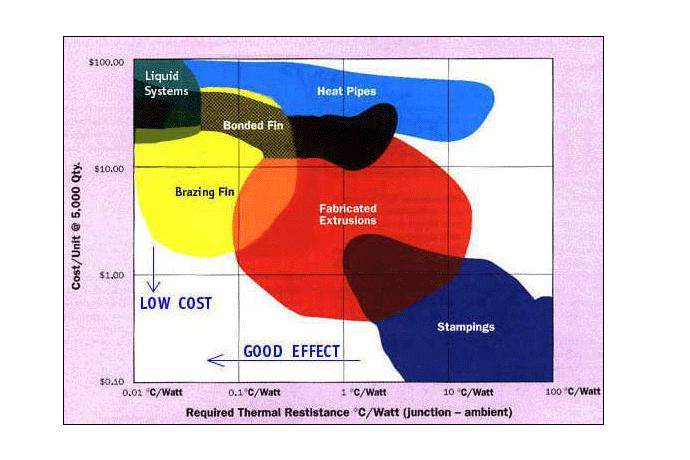

Trends of Heat Sink Technology |

| Series | Technology |

Product Description

Products of HEAT-TECH

-

For Automobiles

-

Evaporator

For Automobiles

-

Condenser

For Automobiles

-

Heater Core

For Automobiles

-

Oil Cooler

For Automobiles

-

Heat Exchanger for Home Appliances

-

Air to Air Heat Exchanger

Heat Exchanger for Home Appliances

-

2Phase Heat Exchanger

Heat Exchanger for Home Appliances

-

for PTC Heater Heat Sink

Heat Exchanger for Home Appliances

-

Condenser

Heat Exchanger for Home Appliances

-

Heat Sink Designed for Cooling Electronic and Communication Equipment

-

Corrugate Fin Heat Sink

Heat Sink Designed for Cooling Electronic and Communication Equipment

-

Plate Heat Sink

Heat Sink Designed for Cooling Electronic and Communication Equipment

-

Lattice Type Heat Sink

Heat Sink Designed for Cooling Electronic and Communication Equipment

-

Plate Type Heat Sink

Heat Sink Designed for Cooling Electronic and Communication Equipment

-

Industrial Heat Exchanger

-

Head Spreader

Industrial Heat Exchanger

-

Forrugate Fins

Industrial Heat Exchanger

-

for Heat-Elect

Industrial Heat Exchanger

-

for Oil Pressure Cooler

Industrial Heat Exchanger

-

Technology

-

Trends of Heat Sink Technology

Technology

-

Brazing Method

Technology

-

Heat Exchanger Process

Technology