The diluted solutions stirred in the storage tank are transferred to the pump and spayed in the drying chamber.

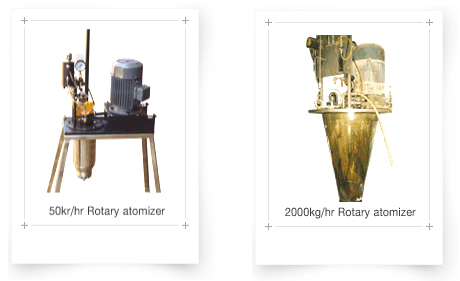

The spray system consists of two types ; a rotary atomizer and a high pressure atomizer. The rotary atomizer sprays the fluid horizontally using centrifugal force by putting the fluids into the rotating disk.

The high pressure atomizer sprays using a high pressure pump and nozzle.

The two methods are most frequently used for commercial purposes.

There are other kinds of spray systems such as air atomizing and an ultrasonic method that can be used in laboratories.

Our company can produce all kinds of sprays to response to the needs of customers based on accumulated experience and expertise.

We produce our spray discs using all kinds of materials including ZrO2, SiC, Si3N4, etc as well as using a super light alloy.

Our rotary atomizer has realized perfect operation without need of repair for 10,000 hours by adapting non-fueling system for small and medium-sized rotary atomizers.

Only for the large sized rotary atomizer, is a forced circulation fueling system used.

For the hot blast generator used in drying procedure, there are electric heating types that are suitable for smal-sized sprayer.

Also there is a gas- direct combustion type that has high thermal efficiency and a clean energy system; a steam heater type using stream; a bunker-C, oil-direct combustion type, other direct combustion types, indirect combustion type, heat transfer oil heater type, etc. We can produce any kind of hot blast generator according to the needs of the customer and powder quality.