▷ Special Characteristics

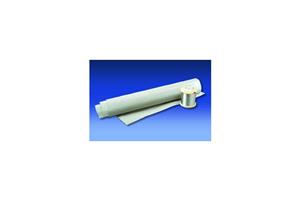

· Bright and Shiny Surface

· Superior coiling efficiency

· Quality Guarantee according to

applications

▷ Grade : AISI 302, 304, 304N1, 305, 316

and etc.

▷ Diameter : 0.080mm ~ 5.00mm

▷ Packing : Coil, Spool

▷ Surface Finish : Bright/Dull

Packing Type

| Grade | Chemical Composition (%) | ||||||||

| C Max. | Si Max. | Mn Max. | P Max. | S Max. | Ni | Cr | N Max. | Other | |

| 302 | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 8.0∼ 10.0 | 17.0∼ 19.0 | 0.10 | - |

| 304 | 0.08 | 1.00 | " | 0.045 | 0.030 | 8.0∼ 10.5 | 18.0∼ 20.0 | 0.10 | - |

| 305 | 0.12 | 1.00 | " | " | " | 10.5∼ 13.0 | 17.0∼ 19.0 | - | - |

| 316 | 0.08 | 1.00 | " | " | " | 10.0∼ 14.0 | 16.0∼ 18.0 | 0.10 | Mo2.0∼ 3.0 |

JIS G 4314

Diameter | Tolerance (mm) | Ovality | Tensile Strength N/㎟(Kgf/㎟) | |

A Class(WPA) | B Class(WPB) | |||

302 / 304 /316 | 302 / 304 | |||

0.15 - 0.20 | ±0.005 | Max. 0.005 | 1650(169) - 1900(193) | 2150(220) - 2400(244) |

0.201 - 0.26 | ±0.008 | Max. 0.008 | 1600(164) - 1850(188) | 2050(209) - 2300(234) |

0.261 - 0.40 | ||||

0.401 - 0.60 | ±0.010 | Max. 0.010 | 1950(199) - 2200(224) | |

0.601 - 0.80 | 1530(156) - 1780(181) | 1850(189) - 2100(214) | ||

0.801 - 0.90 | ±0.015 | Max. 0.015 | ||

0.901 - 1.00 | ||||

1.001 - 1.40 | 1450(148) - 1700(173) | 1750(179) - 2000(203) | ||

1.401 - 1.60 | 1400(143) - 1650(168) | 1650(169) - 1900(193) | ||

1.601 - 2.00 | ±0.020 | Max. 0.020 | ||

2.001 - 2.60 | 1320(135) - 1570(160) | 1550(159) - 1800(183) | ||

2.601 - 3.20 | 1230(126) - 1480(150) | 1450(148) - 1700(173) | ||

3.201 - 4.00 | ±0.025 | Max. 0.025 | ||

4.001 - 5.00 | 1100(113) - 1350(137) | - | ||

ASTM A 313

Diameter | Tolerance In. | Ovality | Type 302 / 304 | Type 305 /306 |

Tensile Strength,ksi(MPa) | Tensile Strength,ksi(MPa) | |||

incl 0.0080(0.20)-0.009(0.23),incl | ±0.0003 | Max. 0.0004 | 325(2240)-355(2450) | 245(1690)-275(1895) |

over 0.009(0.23)-0.010(0.25),incl | 320(2205)-350(2415) | |||

over 0.010(0.25)-0.011(0.28),incl | 318(2190)-348(2400) | 240(1655)-270(1860) | ||

over 0.011(0.28)-0.012(0.30),incl | 316(2180)-346(2385) | |||

over 0.012(0.30)-0.013(0.33),incl | 314(2165)-344(2370) | |||

over 0.013(0.33)-0.014(0.36),incl | 312(2150)-342(2360) | |||

over 0.014(0.36)-0.015(0.38),incl | 310(2135)-340(2345) | |||

over 0.015(0.38)-0.016(0.41),incl | 308(2125)-338(2330) | 235(1620)-265(1825) | ||

over 0.016(0.41)-0.017(0.43),incl | ±0.0004 | Max. 0.0004 | 306(2110)-336(2315) | |

over 0.017(0.43)-0.018(0.46),incl | 304(2095)-334(2300) | |||

over 0.018(0.46)-0.020(0.51),incl | 300(2070)-330(2275) | |||

over 0.020(0.51)-0.022(0.56),incl | 296(2040)-326(2250) | |||

over 0.022(0.56)-0.024(0.61),incl | 292(2015)-322(2220) | |||

over 0.024(0.61)-0.026(0.66),incl | 291(2005)-320(2205) | 235(1620)-265(1825) | ||

over 0.026(0.66)-0.028(0.71),incl | 289(1995)-318(2190) | |||

over 0.028(0.71)-0.031(0.79),incl | 285(1965)-315(2170) | |||

over 0.031(0.79)-0.034(0.86),incl | ±0.0006 | Max. 0.0006 | 282(1945)-310(2135) | |

over 0.034(0.86)-0.037(0.94),incl | 280(1930)-308(2125) | |||

over 0.037(0.94)-0.041(1.04),incl | 275(1895)-304(2095) | |||

over 0.041(1.04)-0.045(1.14),incl | 272(1875)-300(2070) | 230(1585)-260(1790) | ||

over 0.045(1.14)-0.050(1.27),incl | 267(1840)-295(2035) | |||

over 0.050(1.27)-0.054(1.37),incl | 265(1825)-293(2020) | 225(1550)-255(1760) | ||

over 0.054(1.37)-0.058(1.47),incl | 261(1800)-289(1990) | 220(1515)-250(1725) | ||

over 0.058(1.47)-0.063(1.60),incl | 258(1780)-285(1965) | |||

over 0.063(1.60)-0.070(1.78),incl | ±0.0008 | Max. 0.0008 | 252(1735)-285(1935) | 215(1480)-245(1690) |

over 0.070(1.78)-0.075(1.90),incl | 250(1725)-278(1915) | |||

over 0.075(1.90)-0.080(2.03),incl | 246(1695)-275(1895) | 210(1450)-240(1655) | ||

over 0.080(2.03)-0.087(2.21),incl | 242(1670)-271(1870) | 205(1415)-235(1620) | ||

over 0.087(2.21)-0.095(2.41),incl | 238(1640)-268(1850) | |||

over 0.095(2.41)-0.105(2.67),incl | 232(1600)-262(1805) | 200(1380)-230(1585) | ||

over 0.105(2.67)-0.115(2.92),incl | 227(1565)-257(1770) | 195(1345)-225(1550) | ||

over 0.115(2.92)-0.125(3.17),incl | 222(1530)-253(1745) | |||

over 0.125(3.17)-0.135(3.43),incl | ±0.0010 | Max. 0.0010 | 217(1495)-248(1710) | 185(1275)-215(1480) |

over 0.135(3.43)-0.148(3.76),incl | 210(1450)-241(1660) |

Diameter(mm) | Surface | Coating | Packing(Kg) | ||

Bright | Dull | W't/Coil(Coil I/D) | W't/Spool | ||

0.15-0.29 | O | - | No | - | 11(DIN200) |

0.30-0.39 | O | - | ″ | 8(8 In.) | 20(DIN250) |

0.40-0.60 | O | - | ″ | 15(10 In.) | 20(DIN250) |

0.60-0.79 | O | - | ″ | 25(12 In.) | 20(DIN250) |

0.80-0.99 | O | O | Option(Dull) | 30(14 In.) | - |

1.00-1.79 | O | O | ″ | 50(16 In.) | - |

1.80-4.20 | O | O | ″ | 100(24 In.) | - |