KR TECH has vast expertise in the ion implant market, so it was a straight-forward decision for us to enter the solar market.

We manufacture the beam line magnets, vacuum chambers and many other machined hi- tech parts. Some of the technology used in this field is state of the art. The fact that a silicon wafer can now be implanted in a similar way to a silicon chip, has made Solar a lot more cost effective.

KR TECH manufactures for many companies around the world breaking into this new source of energy. The implanted solar panel is at least 7% more efficient than the previous panels, thus making solar a lot more cost effective for the consumer.

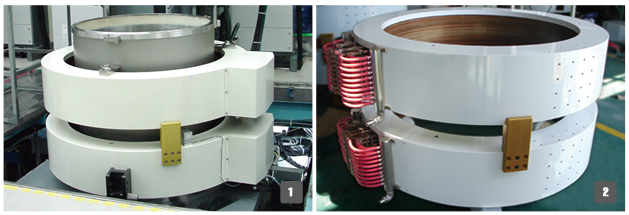

① Retrofit-magnet

Helping growth of single crystal for semiconductor wafers

Type _ 4,5,6,8,12 inch

②

500A, 113V

Outdia. : 1.6m

Weight : 1 ton India. : 1.3m

Height : 2.7m

Field : 800 gauss

A magnetic field produced by magnet systems made in our company can be applied in the CZ system in order to damp the oscillations in the melt. The process is called magnetic Czochralski crystal growth (MCZ). The applied field creates an electric current distribution and an induced magnetic field in the electrically conducting melt. This produces a Lorentz force that influences the flow and reduces the amplitude of the melt fluctuations.

The melt flow is driven by the forced convection due to the rotations of the crucible and the crystal, by Grashof and Marangoni convections due to temperature differences in the melt and by the Lorentz force due to both external and induced magnetic fields