Description

Automatic machine can be manufactured with higher rigidity, accuracy and cost efficiency when the lesser impact is transmitted between the output part and the driving sources such as intermittent / shaking / continuous rotation.

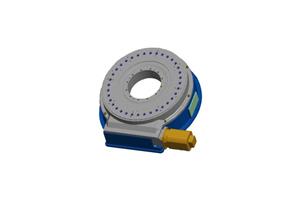

In 1993, We, Yanghean released the CF series which has the flat surface for combining table, arm, sprocket and other devices with the output shaft. Also we provide special option of center-thru output shaft for easy storing and repairing of cables and pipes around.

Remarks

1. Wide range of sizes

Standardized the size for the axial distance (shaft-to-shaft) of 45~450mm to be broadly used from small sized electrical parts to large assembled products, and machining center for transferring and heavy cutting.

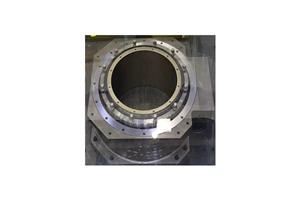

2. High Efficiency / High capacity / High Accuracy

Heat-treated and precisely grinding machined CAM and Cam-follower bearing enable operation with high efficiency, high capacity and high accuracy without backlash and vibration during high speed driving.

3. Universal Mounting

Every 6 direction available for mounting provides flexible designing.

4. High speed Rotating

precisely processed Cam, Cam-follower bearing, splitter plate make no vibration and noise during high speed rotation made within oil box, which makes no heat from friction.

5. Wide range of options

Various options such as Torque limiter, Reducer, Clutch, Brake are mountable.

Product(Size) List

045 050 060 070 080 110 140 160 180 250 300 350 400 450