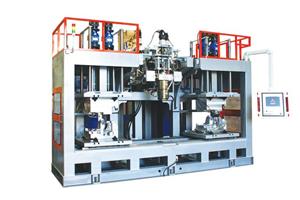

Our electric blow molding machine is that improving the structure of the molding machine for producing high-quality molded products stable with the research operation and for convenience,improved operating rate, the production effiency of high-speed molding stability.

We are commited to maximizing the development.

Feature & Strength.

Increasing of economics

– Servo motor driven only when necessary these days, that cost is urgentry required in accordance with the increaseof electricity rates.

It can be employed to reduce the power cost of at least about 30% compared to the molding machine of the hydraulic system.

– Since the necessary exchange of such exchange or regularly hydraulic seal, oil seal required in the hydraulic molding machine.

Accordingly It’s possible significant savings in maintenance costs.

Minimize electric power use

Our electric blow molding machine can operate efficiently with only the cooling power consumption of approximately 20% compared to hydraulic blow molding machine, 80% of coolant being used for hydraulic machine is mainly to cool down hydraulic oil. In conclusion, We are not using the hydraulic oil.

Improvement of the working environment

– Operation of our electric molding machine in a clean environment with low noise is driven by a servo motor and air cylinder It can work no pollution caused by oil dust , failure of the product due to oil adhesion, etc. A clean workplace to be concerned about the optimum machine.

Ensure precise control and stbiliity of quality

– There is control of the operating panel to the adoption of a servo motor is digitized and the driving position is fine to a certain operating time. And the production has stabilized, according to the setting time and the difficulty in changing the molding conditions of the product changes, It can quickly and easily resolved.

– Movement without the impact at the fastest speed in segment of the transfort and closing the drive of the servo motor. There is no strain on the structure , depending on the parison controller and precise control of cycle time and the extruder swing unit. You can generate high-quality molded products through the control of weight and irregular thickness.