•Increased efficiency of heat exchange by adopting inner grooved copper tube.

•Electric defrost (U-heater)

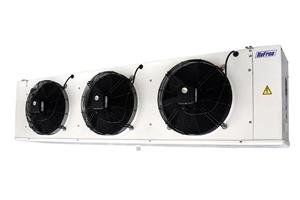

•Increased air throw by FAN GUIDE GRILL.

•Applied Double drain pan.

•Applied PVC TERMINAL BOX (IP55)

•Electric wire is connected by specially designed terminal plate & easy to access.

•Applied Aluminum case.

•Adapted HACCP standard by NSF approved painting for powder coating.

•Applied ZIEHL-ABEGG / ebm outrotor.

•Easy to replace socket/plug connection for motor.

- Electric application for fan motor is 1PH 220V /3PH 380V, 60Hz

- Air throw is determined the air velocity 0.5m/s

- Areas should be avoided corrosive vapors or inflammability materials as polluted air.

- Specification is subject to change without a notice for improvement

•Increased efficiency of heat exchange by adopting inner grooved copper tube.

•Electric defrost (U-heater)

•Increased air throw by FAN GUIDE GRILL.

•Applied Double drain pan.

•Applied PVC TERMINAL BOX (IP55)

•Electric wire is connected by specially designed terminal plate & easy to access.

•Adapted HACCP standard by NSF approved painting for powder coating.

•Applied ZIEHL-ABEGG / ebm outrotor.

•Easy to replace socket/plug connection for motor.

- Electric application for fan motor is 1PH 220V /3PH 380V, 60Hz

- Air throw is determined the air velocity 0.5m/s

- Areas should be avoided corrosive vapors or inflammability materials as polluted air.

- Specification is subject to change without a notice for improvement