Linear type, Roll-fed label(Eye-mark, Servo motor control), Hot-melt glue,

High speed Labeller, who is efficiently used for the flexible application at the various material

label, such as paper, OPP, PVC and paper laminates, etc., and various containers

(Glass, PET, PE and can), with advantages at a lower label cost by means of roll-fed labels,

Min. installation space, simple/quick change part, more/better advertizing space/appearance

by wrap-around labelling, suitable for food, beverage and dairy industry.

Control Features

Servo motor control system

Touch screen control panel

- User-friendly graphic design

- Operation data: Easy call-up/revision

- One touch change-over: label length, cut position

- Self diagnosis and alarm system

Continuous label length data monitoring system

Auto start-up by auto registration tracking function.

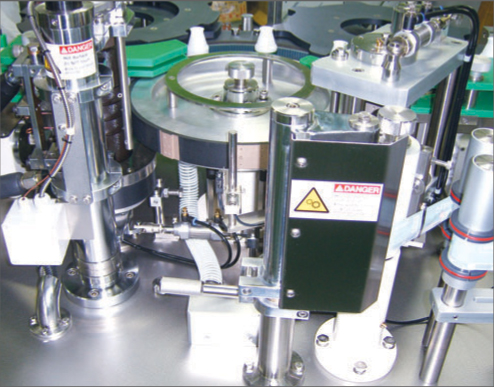

Safety devices

- Auto torque guard: Star wheel jam, auto M/C stop

- No-bottle, No-label

- Bottle jam/fall-down, Auto machine stop

- No-bottle check

- Over-bottle check

Low air pressure, auto M/C stop with alarm

Heater cut-off, auto M/C stop with warning message.

Mechanical / Operational Features

Strong base frame structure

- Vibration-proof and noise absorbing construction

- Stainless steel base-frame top covering

- Corrosion-proof painting

Rapid change-over for different size by modular design (20 Min without tool)

Data coding by jet printer at correct spot before label cut (option)

Min. influence of label / container meet point owing to container tolerance

Heat treatmented drive gears rather than chain: No timing change

Use separate vacuum pump in vacuum and cutting drum: Uniform vacuum degree

Compact machine size: Min. space required

Glue supply system

- Heat-distortion free due to its special structure stood with heat-resistance & lubrication-free bearings

- Uniform thickness glue-spread on drum

- Long life time

Rotary cutter

- Precise smooth cuts at any speed

- Easy knife gap adjustment and replacement

- Quiet operation through Min. noise and vibration

Reel stand

- Mechanical & electric brake system

- Uniform label tension at any speed

Operator-free operation except start-up and label roll change

Vacuum manifolder: Use special material to secure

abrasion/distortion-proof design

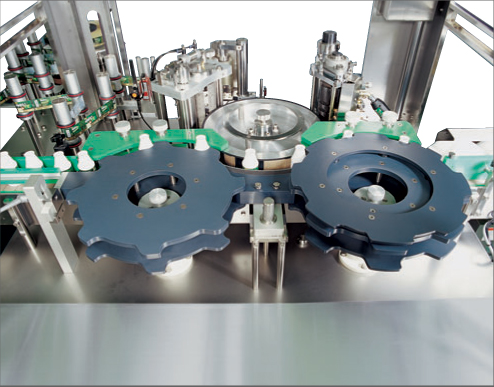

1. FEED WHEEL AND ROLL-ON PAD

* Precise label application.

* Removing rotation inertia at discharge star wheel provides smooth container discharge.

2. HANDLE ORIENTATION PART

* Orientation of label at desired position for containers with handle.

3. DRUM PART

* Glue application at both label ends at vaccum drum.

* Easy to access to the important positions via open type design.

Specification

|

VACUUM |

CAPACITY |

BOTTLE DIAMETER |

LABEL LENGTH |

||

|

420 / 3P |

12,000- |

MIN |

MAX |

MIN |

MAX |

|

50mm |

120mm |

150mm |

385mm |

||

|

420 / 4P |

15,000- |

MIN |

MAX |

MIN |

MAX |

|

40mm |

85mm |

135mm |

275mm |

||

|

480 / 2P |

6,000 |

MIN |

MAX |

MIN |

MAX |

|

80mm |

160mm |

200mm |

600mm |

||

|

480 / 4P |

24,000 |

MIN |

MAX |

MIN |

MAX |

|

50mm |

100mm |

180mm |

320mm |

||